September 16, 2020

68RFE Overdrive Clutch Failure: What to Check First When Troubleshooting OD Issues

Jason Larochelle

The Chrysler 68RFE was utilized in the ’07–’20 Dodge Ram 2500 and 3500 with the high-torque output 6.7L Cummins Diesel engine. It’s perhaps the fastest growing market today for transmission builders, in part due to an increase in popularity from truck enthusiasts — who are modifying them to never- before-seen power and torque levels — plus the sheer number of these units on the road. One of the top complaints about this transmission is how prone it is to overdrive clutch failure. Identifying the exact cause goes beyond pointing fingers at limited clutch capacity, though, as the 68RFE OD system is quite complex. Checking a few key failure points for problems when you’re making repairs or upgrading the transmission is critical for having confidence in your build.

Although the 68RFE shares similar design features with the 45RFE, it has come a long way in all aspects considering the 45RFE was used in much smaller applications such as the 3.7L Jeep Liberty. The diesel aftermarket in general has grown significantly, and the 6.7L is capable of making significantly more power than what it comes with from the factory. However, when modifying a vehicle for bigger power, it seems to be a trend to overlook the transmission as a necessary area to upgrade. Perhaps it is overlooked because it is more exciting to be bragging to buddies about installing a 6" lift, 35’s and a tuner than telling them about upgrading the input shaft. Overlooking the details will almost always spell trouble in life, though, especially in a transmission.

Failure Point #1: Fragile Overdrive Clutches

The most common failure point of the 68RFE is the Overdrive clutches. The OD clutch assembly from OE has significant weak points, even at stock power levels. Add increased engine power, larger tires or a heavy load, and there is a very high probability this will be the first failure of the 68RFE. Thin frictions that are prone to warping under heat, and a housing that allows enough flex to increase clearances out of specifications, further contribute to the problem.

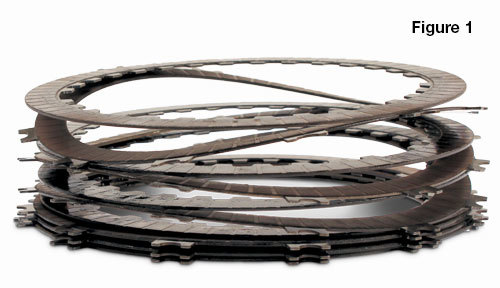

Taking a look at the clutches first, we find that they are single sided, and the steel core is only .034" thick. These are some of the thinnest clutches to be installed in any transmission. For comparison, the OE steels in the direct clutch pack of a 4L80-E are .080". Because of their lack of mass, the 68RFE clutches have a very low tolerance to heat and do not dissipate it well. Once these clutches heat up past a certain temperature, they begin to distort. This decreases the overall clearance and causes the clutches not to release fully, eventually burning up (Figure 1).

| Figure 1 – 68RFE Clutch Pack Distorted by Heat Damage |

|---|

|

| Fragile, thin (.034"), single-sided OE clutches are a primary cause of 68RFE OD clutch burn up. Distorted clutches take clearance out of spec, making burn up inevitable. |

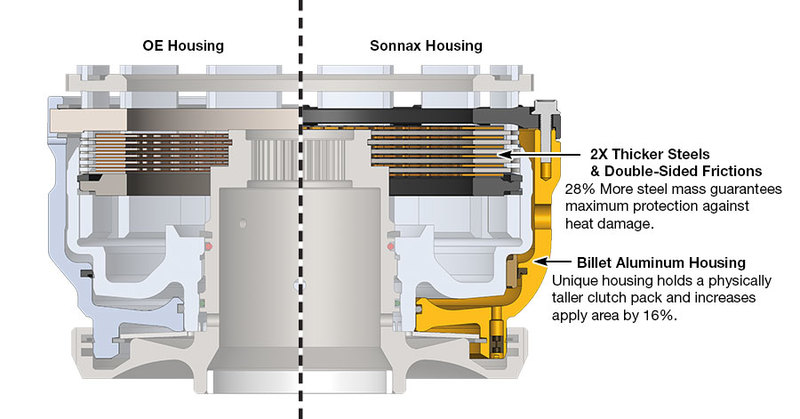

In the past, there were few good options for dealing with 68RFE Overdrive clutch failure, common methods being valve body/pump modifications or adding expensive, extra components. Today, the option preferred by most professionals and DIYers is to simply install the Sonnax Smart-Tech® overdrive clutch housing kit. As shown here, the upgraded housing is designed to hold a taller clutch pack built with thicker steels that can take the heat. The result is 20% more clutch capacity, right out of the box.

|

Although it is easy to place the full blame on the insufficient clutch pack for the OD failure, distorted clutches are only the first visible symptom; there are actually several other underlying causes of this failure.

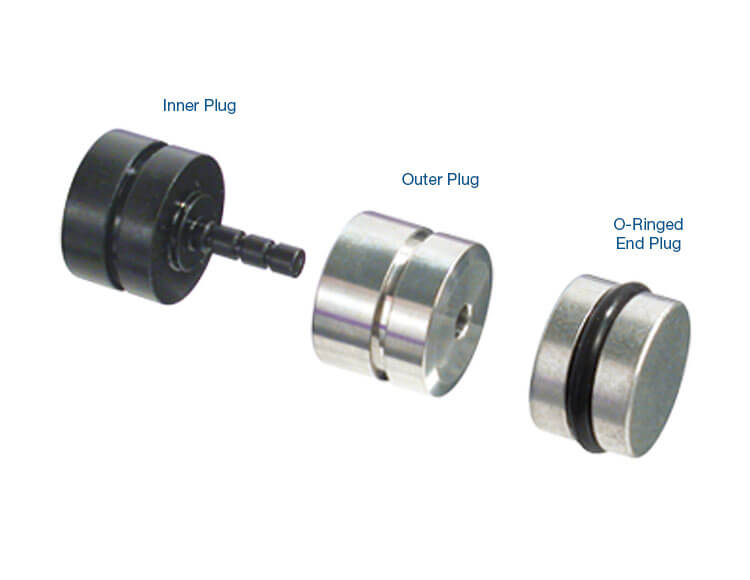

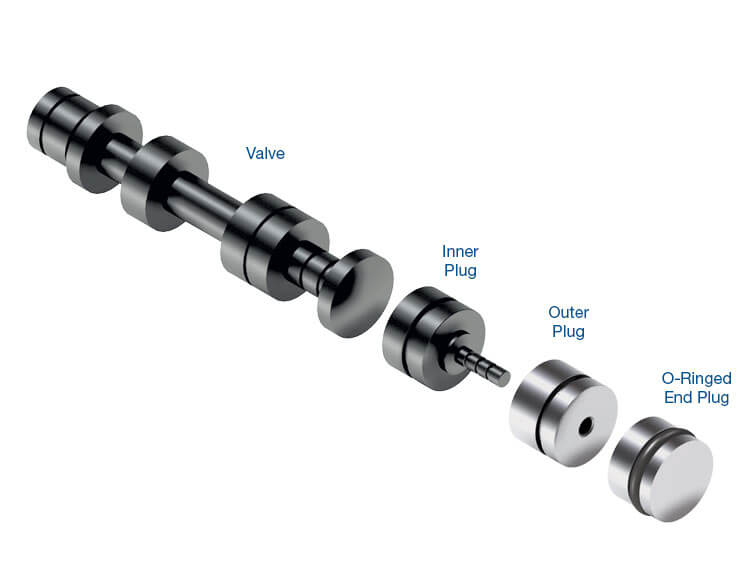

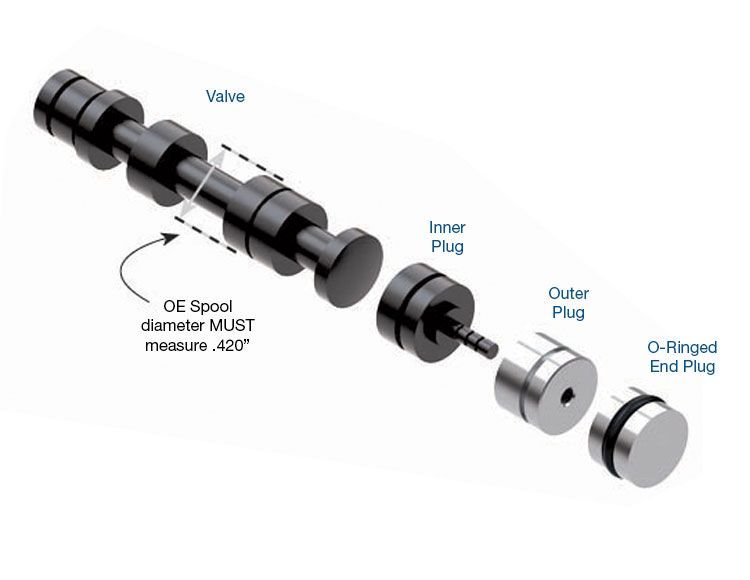

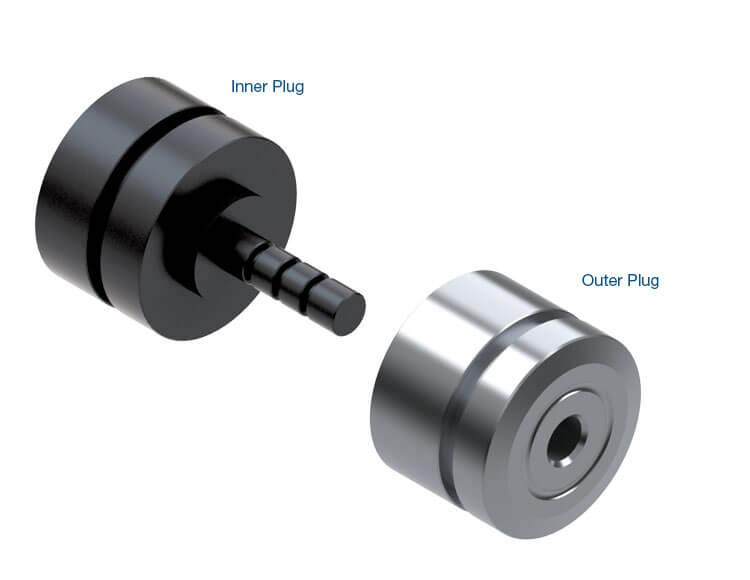

Failure Point #2: Leaking Solenoid Switch Valve Plugs

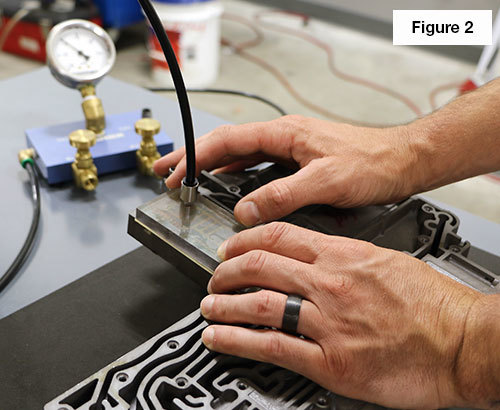

Arguably the weakest link of the Overdrive clutch system is the solenoid switch valve plugs. These valves and plugs cycle frequently and over time wear down the casting, which causes crossleaks into and out of the OD circuit. OD pressure losses transfer into a lower clutch holding force, which allows the clutches to slip, heat up and prematurely fail. While fixing the plugs should be your primary concern, as they have the most to do with OD failure, it is still a good idea to inspect and address the switch valve itself, as it can contribute to the problem. Vacuum testing the bore is an ideal diagnostic technique that will allow you to reliably identify the location of leaks and their severity (Figure 2). A detailed guide to vacuum testing RFE units is available free at www.sonnax.com/vactest.

| Figure 2 – Vacuum Testing the 68RFE Solenoid Switch Valve Bore |

|---|

|

Again, the aftermarket has developed fixes for this issue. Sonnax offers innovative, drop-in parts whose design and material outperform OE components. If vacuum testing indicates bore wear is severe, the bores should be reamed out and Sonnax oversized valves installed to restore hydraulic pressure. See links to Sonnax solenoid switch valve repairs at the end of this article.

Failure Point #3: Weak Overdrive Clutch Housings

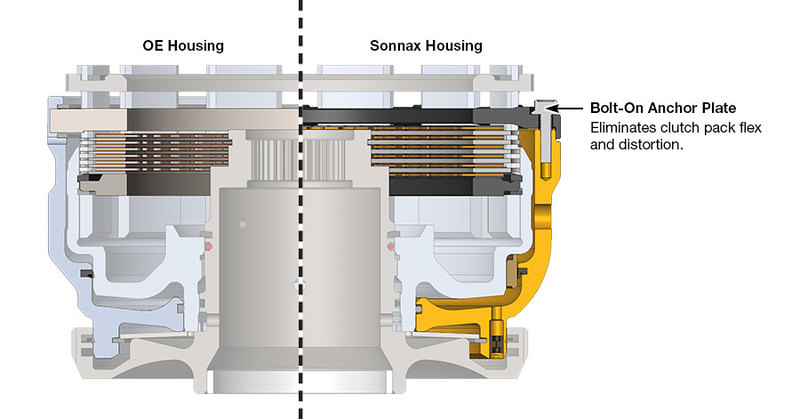

The OE Overdrive housing itself can lead to the failure of the clutches by allowing excessive flex that causes the OD frictions to heat up preemptively. We have seen this same issue in the 4L60-E input drums in the past. The top of the OE housing is not strengthened or supported and is able to flex, much like squeezing the top edge of a salad bowl. Luckily, the aftermarket was quick to respond to this shortfall with strengthened Overdrive drums to stop the flex and keep the frictions within clearance tolerance. This is another key feature of the Sonnax Smart-Tech overdrive clutch housing kit, whose bolt-on anchor plate eliminates 68RFE clutch pack flexing and distortion.

|

Faiture Point #4: Worn Inner Retainer Housing

Hard-working applications are at high risk for overdrive failure due to clutch wear on the inner retainer housing. The OD clutches are applied in 5th & 6th Gears where the vehicle spends most of its miles. Damage builds up over time, causing the clutches to drag, affecting proper apply and release. To eliminate all risk of wear, Sonnax heavy duty inner retainer housing kits feature a specially modified OE retainer and hardened steel inserts that prevent wear of the housing from the overdrive clutches.

|

Failure Point #5: Incorrect Line Pressure

Incorrect line pressure, whether too low or too high, can cause 68RFE Overdrive issues as well.

Low line pressure does not provide the necessary apply force to the OD clutches. Insufficient apply force will allow slippage, which creates heat that will burn up the clutches. Low line pressure can go unnoticed by a failed line pressure sensor. Yes, line pressure can be verified on professional scan tools, but keep in mind the sensor itself should be verified for accurate diagnosis. OE line pressure adapter tool No. 8259 (Figure 3) installs into the case in place of the line pressure sensor. The line pressure sensor and mechanical pressure gauge are then installed onto the tool. This allows the technician to verify main line pressure and the correct operation of the sensor itself.

| Figure 3 – OE Line Pressure Adapter Tool No. 8259 |

|---|

|

High line pressure can push its way through excessive clearance in the SSV bore and partially apply the OD clutches and/or keep them from releasing. This condition usually triggers the P0871 code. High line pressure can also push its way through the poorly sealing OE separator plate against a roughly macined casting. The separator plate in this instance is just a piece of thin piece of steel. There are now gaskets available to improve sealing.

Failure Point #6: Warped Solenoid Conductor Plate

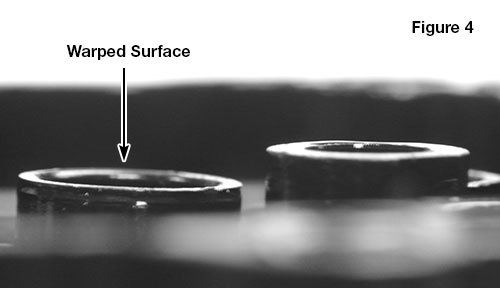

An area that might go unnoticed in diagnosing repeat OD failure is the solenoid block. Because of its design, the solenoid conductor plate is unsupported on one side, while a force is applied via the connector seal. Over time, this constant force allows the solenoid conductor plate to warp, causing OD apply pressure to bleed away from the circuit (Figure 4). Sonnax solenoid spacer and service kit will reliably restore the solenoid block and also prevent circuit board movement that causes intermittent pressure switch codes. If you need to replace a worn or contaminated solenoid block, two styles of RFE remanufactured solenoid blocks are available from Sonnax that are precision tested to OE specifications.

| Figure 4 – Warped 68RFE Solenoid Conductor Plate |

|---|

|

| The warped surface on the left is not parallel with the surface on the right, allowing pressure losses. |

Failure Point #7: Overburdened or Modded Vehicles

If Overdrive failure is not caused by high-mileage issues, there are other factors that can contribute as well. Towing higher-than-recommended weight, for example, puts more strain on the OD circuit and the already weak stock clutches. In the same aspect, emissions deleted, upgraded engine components, extremely oversized tires or vehicles with programmers can cause burn up.

On the issue of vehicles with programmers, keep in mind most of these electronic devices have access to tuning both the engine and transmission characteristics. Some are able to raise line pressure, change shift points and torque converter lockup characteristics. Some are even able to bring TCC on before the 3-4 shift, adding strain on the OD clutch as it applies without the cushion of the non-locked converter. Builders should be careful troubleshooting these vehicles, as the owner could be making changes without being aware of the adverse affects.

Jason Larochelle is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.

Learn More

Related Units

Related Parts

Required

Recommended

Required

Recommended

Required

Recommended

40TE • 40TES • 41AE • 41TE • 41TES • 42LE • 42RLE • 45RFE • 545RFE • 65RFE • 66RFE • 68RFE

Oversized Solenoid Switch Valve Plug Kit 92835-22K

Fits bores containing OE switch valve with .453" dia. large spool only.

-

Helps cure:

- Codes 841, 868, 871, 988, 1775, 1776

- OD clutch burned

- Failsafe mode

- Bind-up

- Wrong gear starts

- TCC apply & release concerns (41 & 42 series)

- Engine stall (41 & 42 series)

- No lockup (41 & 42 series)

Required

Recommended

40TE • 40TES • 41AE • 41TE • 41TES • 42LE • 42RLE • 45RFE • 545RFE • 65RFE • 66RFE • 68RFE

Oversized Solenoid Switch Valve & Plug Kit 92835-31K

Fits bores containing OE switch valve with .453" dia. large spool only.

-

Helps cure:

- Codes 841, 868, 871, 988, 1775, 1776

- OD clutch burned

- Failsafe mode

- Bind-up

- 2nd Gear starts w/MIL on

- 4th Clutch burned

- Engine stall (41 & 42 series)

- TCC apply & release concerns (41 & 42 series)

Required

Recommended

40TE • 40TES • 41AE • 41TE • 41TES • 42LE • 42RLE • 45RFE • 545RFE • 62TE • 65RFE • 66RFE • 68RFE

Oversized Solenoid Switch Valve & Plug Kit 92835-32K

Fits bores containing OE switch valve with .420" dia. large spool only.

-

Helps cure:

- Codes 841, 868, 871, 988, 1775, 1776

- OD clutch burned

- Failsafe mode

- Bind-up

- 2nd Gear starts w/MIL on

- 4th Clutch burned

- Engine stall (41 & 42 series)

- TCC apply & release concerns (41 & 42 series)

Required

Recommended

545RFE • 65RFE • 66RFE • 68RFE

Remanufactured Solenoid Block 44836B-RRP

Fits 65RFE, 66RFE and ’09–’18 545RFE, 68RFE. If supplying a core for your solenoid, please order 44836B-RRP. If no core available, please order 44836B-C.

-

Helps cure:

- Shift concerns

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.