July 15, 2014

Positive Sealing: The Benefits of O-Ringed End Plugs

Maura Stafford

It can be easy to overlook an end plug as a source for various shift complaints, burnt clutches, gear ratio and solenoid codes or converter-related failures. When vacuum testing valve bores or removing the components from a bore to perform a closer visual inspection, we can unknowingly look past the plug and move straight to the key valves for damage or bore wear. Not properly assessing and addressing end plugs can undo all the other great rebuilding you’ve done to the valve body or pump.

In many instances, the end plug is not only the cap keeping the valve and spring in the bore, but it may also function as the primary sealing component to ensure critical fluid pressure gets to the desired location instead of exhausts. And in all instances, the plug acts as a linear stop for the inboard valve or spring, which is the primary reason the plugs can be subject to wear even when they aren’t stroking in the bore.

As the inboard valve strokes to direct fluid pressure, it may repeatedly contact the end plug with some amount of force. As there is some amount of clearance between the plug and casting, and often clearance with the plug and a retainer, this can result in fore/aft or a rocking movement of the plug in the bore and lead to the soft plug wearing. This can take the form of noticeably shiny patches of wear on the plug or multiple scratches parallel to the axis of the plug (Figure 1).

| Figure 1 – Worn OE Plugs |

|---|

|

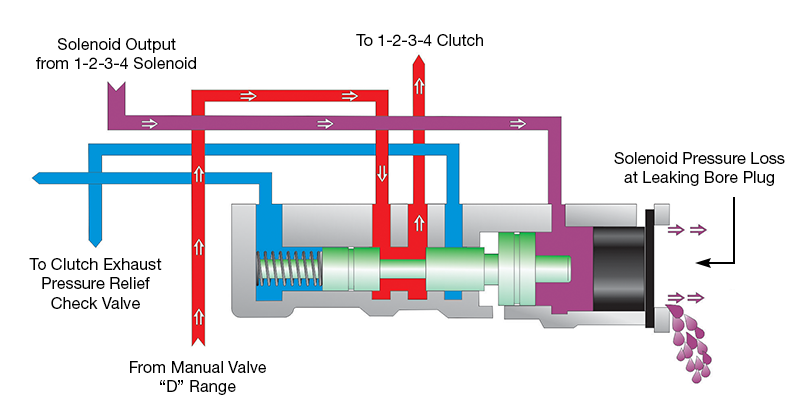

If the spring is in direct contact with the plug, the plug can rotate slightly in the bore as the spring compresses and relaxes, resulting in plug wear. As fluid temperature increases and ATF viscosity decreases, this damage provides a route for the critical oil pressure to go directly to exhaust instead of the intended location, resulting in various drivability complaints (Figure 2).

| Figure 2 – 6R140 1-2-3-4 Clutch Regulator Circuit |

|---|

Plug wear allows solenoid feed oil to exhaust resulting in burnt 1-2-3-4 clutch and delayed engagement. |

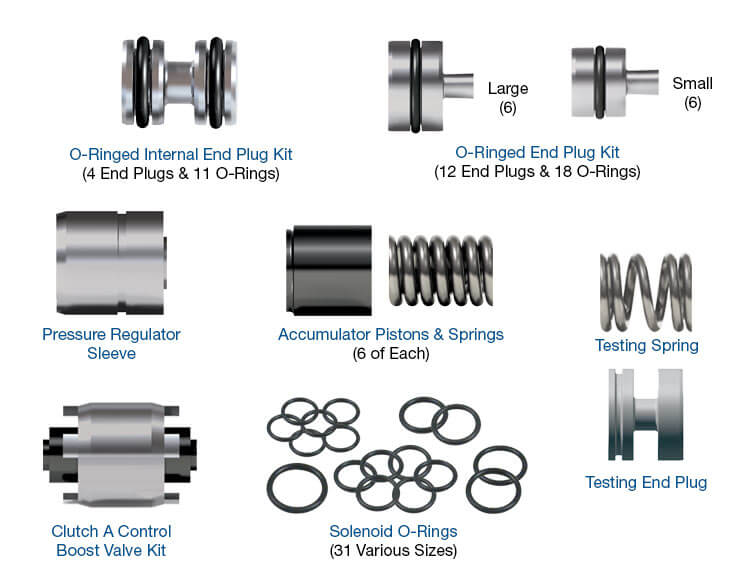

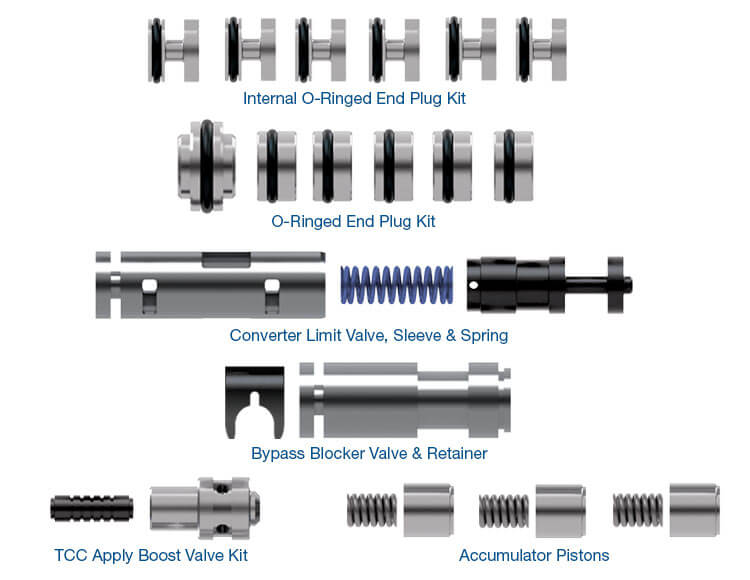

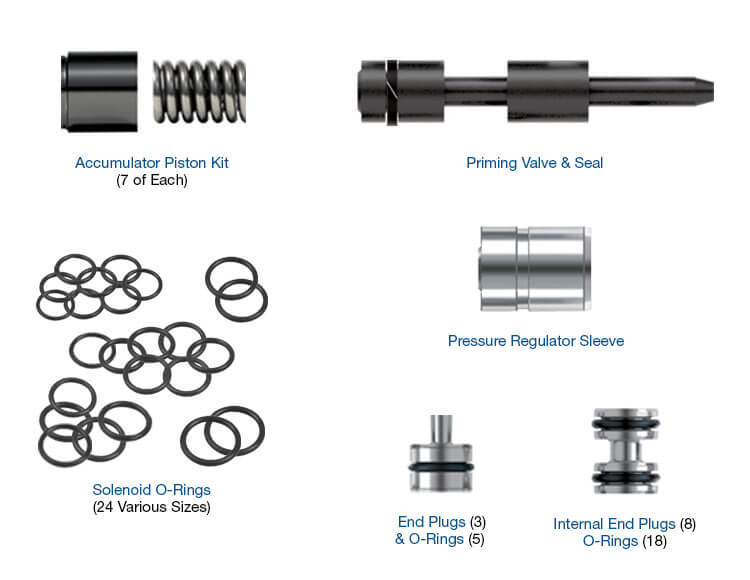

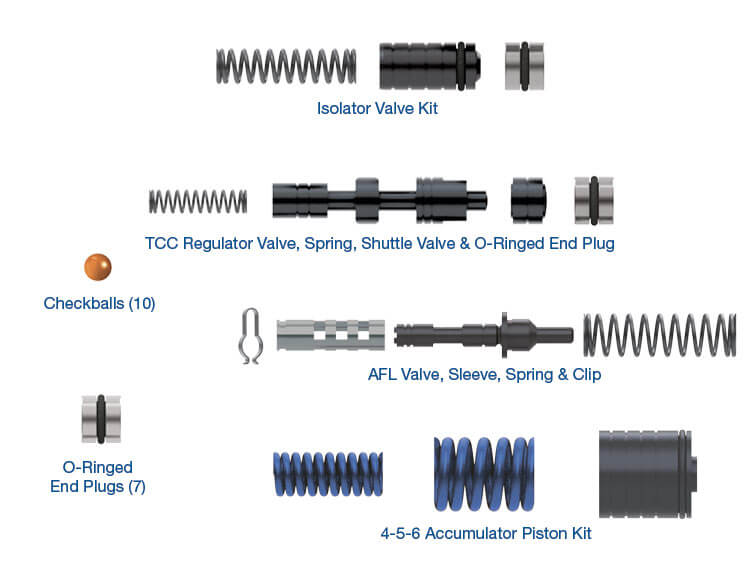

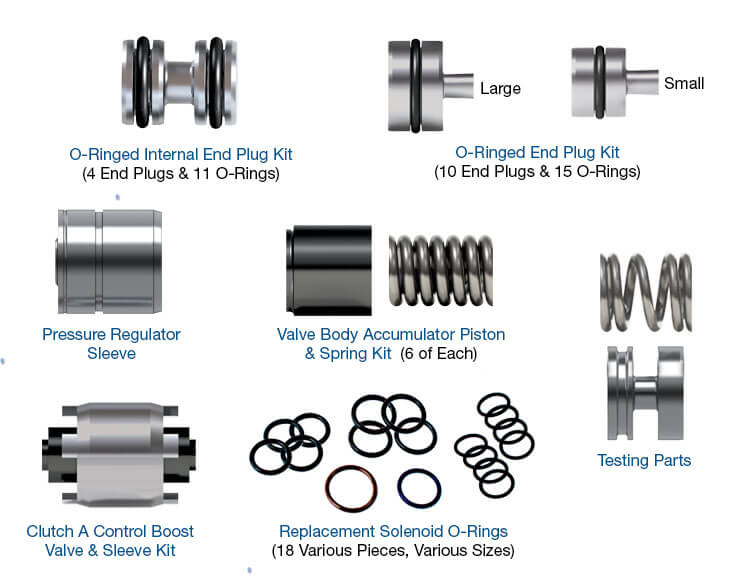

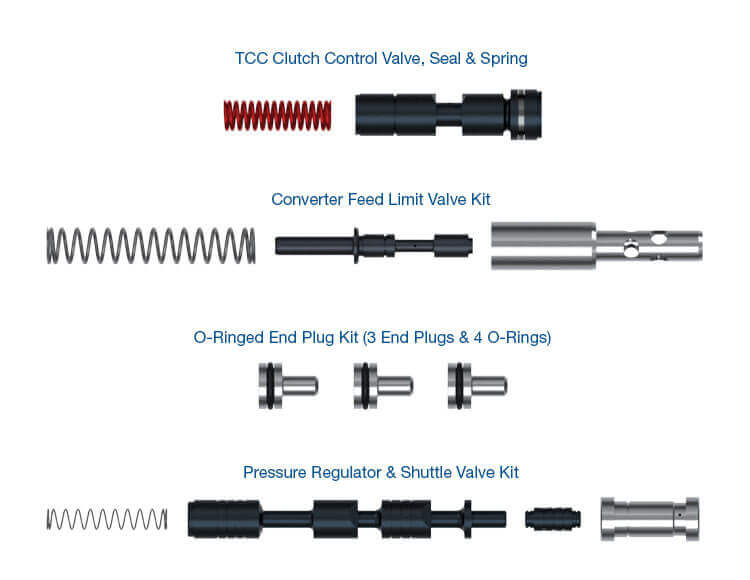

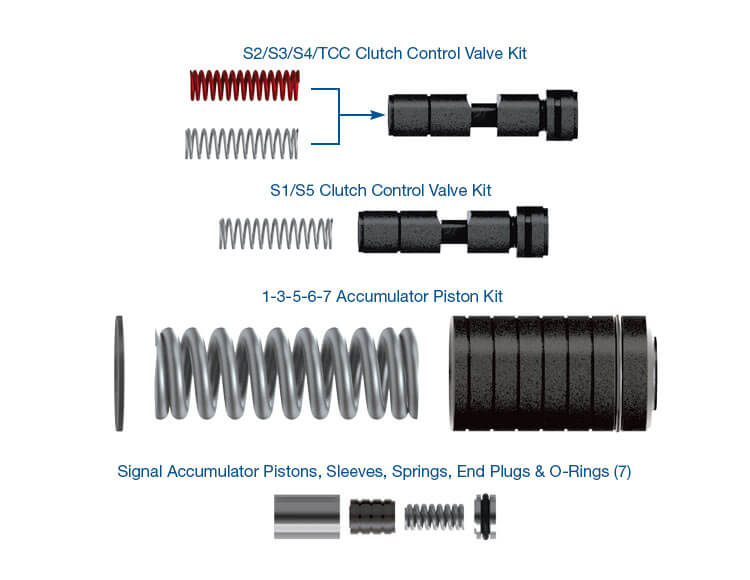

Sonnax offers a wide range of O-ringed end plugs for dozens of applications and includes them as a staple item in all our Zip Kits because the OE plugs tend to be low-mileage wear items that can cause noticeable drivability complaints if not corrected.

By incorporating an O-ring on the Sonnax plug (Figure 3), a positive seal is created with the mating bore, even if it is compromised with wear already. The squeeze of this O-ring material ensures that no critical fluid will leak past the minimal plug-to-bore clearance.

| Figure 3 – Sonnax O-Ringed End Plugs |

|---|

|

O nce these drop-in plugs are installed, the repetitive motions of the inboard valve and spring will not negatively affect the Sonnax plug as they do the OE plugs, resulting in immediate and permanent prevention of leakage at the location.

nce these drop-in plugs are installed, the repetitive motions of the inboard valve and spring will not negatively affect the Sonnax plug as they do the OE plugs, resulting in immediate and permanent prevention of leakage at the location.

Installation is made quick and easy with the use of Sonnax Slippery Stick O-LUBE to lubricate the plug and seal followed by a quick roll on the bench for sizing. So, consider adding another positive fix to your next rebuild, and seal them with Sonnax O-ringed end plugs.

Learn More

October 24, 2018

Eliminate Leakage & Optimize Performance with Sonnax O-Ringed Valves

Related Parts

Required

Recommended

Slippery Stick O-LUBE

Specially formulated lubricant to facilitate O-ring & seal installation

Required

Recommended

Required

Recommended

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.