September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

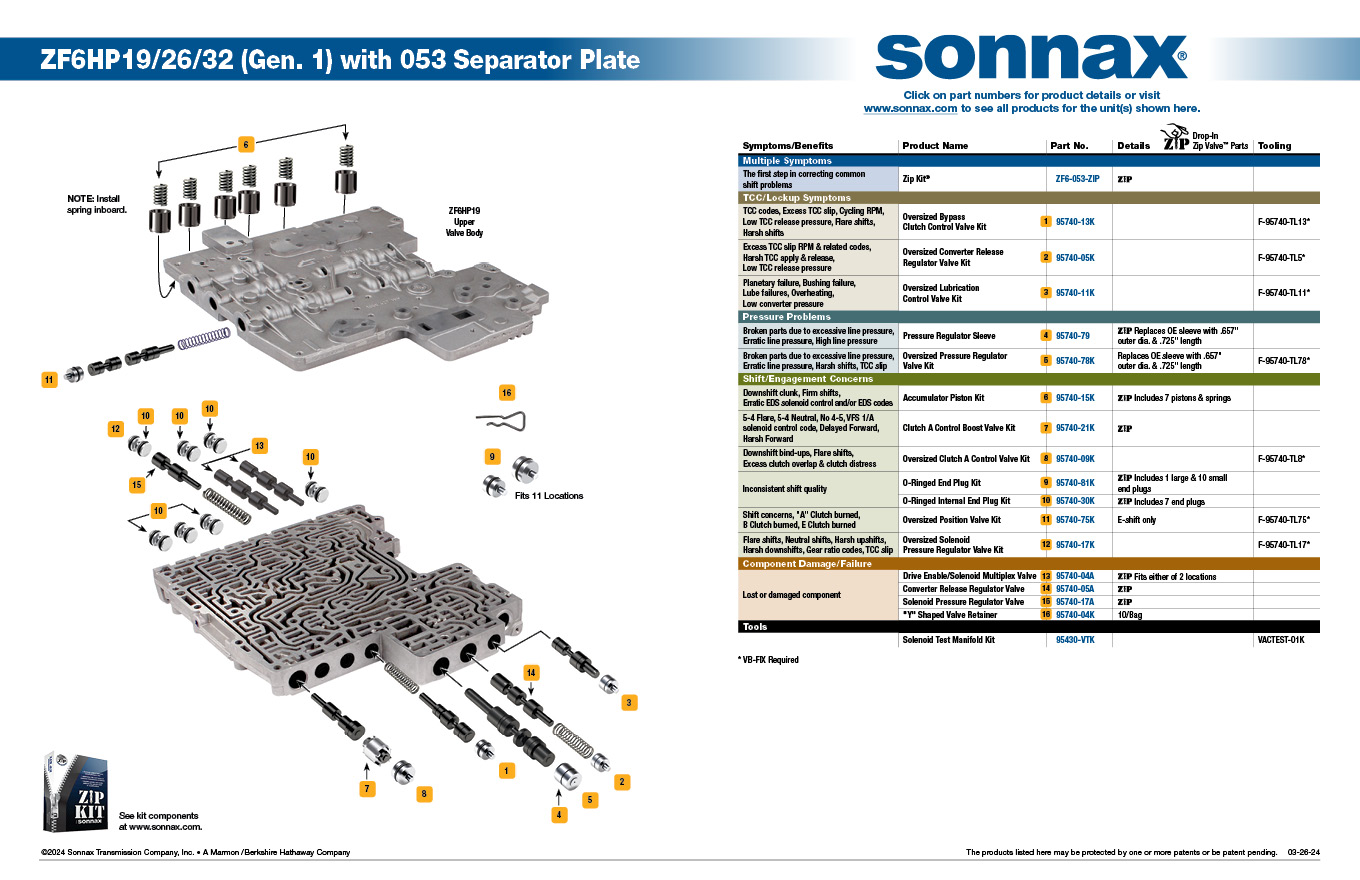

Verify OE valve & sleeve measurements before use.

There are some small diameter and length differences that can cause fit and pressure issues if mismatched into the wrong application. It is recommended to measure the locations shown here to verify that the correct OE or replacement part is fit into the appropriate application during rebuild.

| Application | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| ZF6 Gen. 1, 6R60, 6R75, 6R80 ('09–'14) | .645" | .629" Dia. | .495" Dia. | .568" | .378" | .629" Dia. | .550" Dia. |

| ZF6 Gen. 1 w/ 053 Separator Plate | .725" | .657" Dia. | .511" Dia. | .649" | .378" | .657" Dia. | .586" Dia. |

| ZF6 Gen. 2 | .804" | .629" Dia. | .511" Dia. | .725" | .418" | .629" Dia. | .562" Dia. |

| 6R80 ('15-Later), 6R100 | .645" | .629" Dia. | .511" Dia. | .568" | .378" | .629" Dia. | .550" Dia. |

Vehicles equipped with ZF6HP19/21/32 (Gen. 1) transmissions often develop erratic or high line pressure due to excessive wear in the OE pressure regulator bore and/or sleeve. This wear allows critical oil loss, preventing proper line pressure regulation. Without correct oil pressure, the PR valve will be out of its desired position, resulting in line pressure instability and possibly restricting cooler and lube flow. Reconditioning the bore and installing Sonnax oversized pressure regulator valve kit 95740-78K renews pressure regulator action for revived line pressure control in all ranges.

Kit is NOT compatible with ZF6HP21/28/34 (Gen.2) units. To differentiate between Gen. 1 and Gen. 2 valve bodies, see ZF Identification Guide.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

June 29, 2016

Maura Stafford

January 14, 2014

March 23, 2016

Bob Warnke

June 22, 2016

October 08, 2020

Maura Stafford

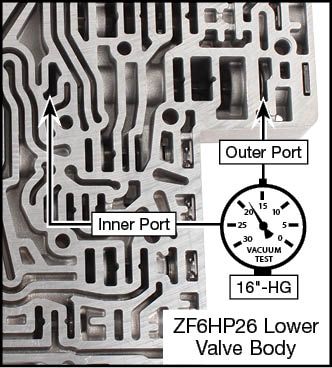

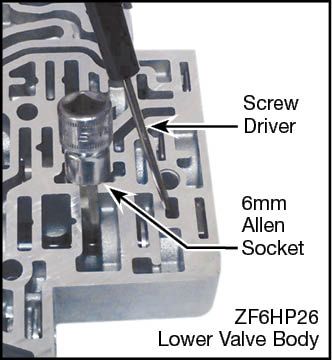

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected. Valve must be positioned as shown to obtain an accurate vacuum test. A 6mm Allen socket and a screwdriver works well for this procedure. Screwdriver pushes sleeve outboard while the Allen socket positions the valve inboard. Vacuum test plate corner will fit snugly between screwdriver and socket to test outer port.