August 01, 2017

How to Recognize & Repair Solenoid Accumulators in Late-Model Valve Bodies

Since the dawn of transmissions, accumulators have been used to cushion the hydraulic apply of clutches and bands. Whether the transmission used modulators or throttle valves and governors, or as the industry moved into EPC and on/off shift solenoids in the ’80s, the same general approach was used: line pressure was directed to an on/off shift valve, which directed apply pressure simultaneously to an apply component and a large accumulator piston. These pistons were generally 1–2 inches in diameter, which also necessitated a large spring for resistance, and could be located in the valve body or the transmission case. These pistons and housing bores are examined for wear during a typical rebuild, as oil loss reduces clutch/band apply pressure and results in various shift-related complaints.

Now enter the dawn of transmissions with six-plus Forward gears, clutch-to-clutch shifting and much more sophisticated solenoids and TCMs. Smoothness of shifts is even more critical, as there are more of them, they are occurring more often and timing between the shifts has shrunk significantly. Yet in some of these types of transmissions, the typical accumulator pistons noted previously do not exist. For instance, in the GM 6L80 the clutches are fed apply pressure through a clutch-specific regulated shift valve and associated clutch boost valve, which are both regulated by a specific PWM pressure control solenoid that is metering actuator feed limit (AFL) pressure to computer demands once input and output speed sensors, TPS information and other inputs are analyzed. There are no “traditional” accumulator pistons, but instead waved clutch plates, compensator feed and clutch exhaust backfill circuits, plus computer controls aiding in the cushioning of the apply components. In diagnosing shift complaints, each of these components and circuits will need to be checked.

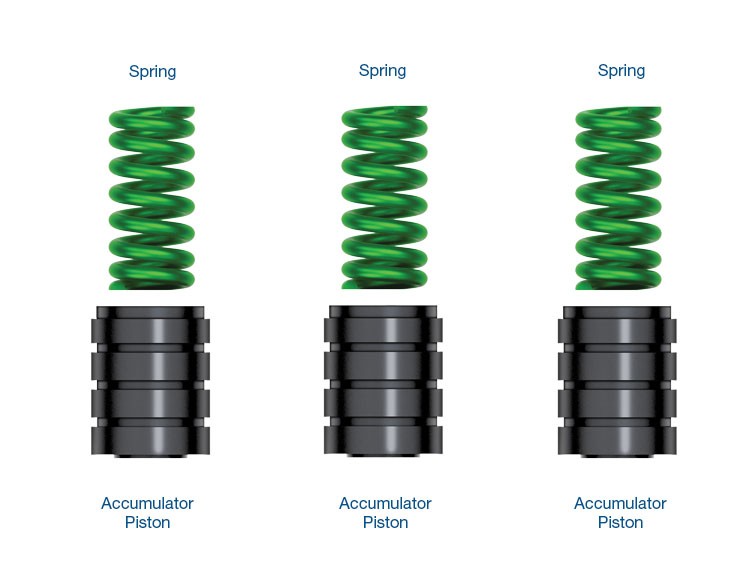

Examination of the GM 6T70 transmission shows an addition to the 6L80 approach. Along with the clutch-specific valves and solenoids, waved clutch plates and new circuits, three small accumulator pistons (two shown in reduced circuit) have been added to the AFL circuit (Figure 1).

| Figure 1: GM 6T70 AFL Circuit |

|---|

AFL pressure is being fed to each of the solenoids. It eventually becomes EPC pressure and the modulated pressure directed to each clutch-specific regulated shift valve and related boost valve, thereby controlling apply pressure to the clutches. So these small accumulator pistons are critical for dampening any pressure inconsistencies in the AFL circuit, which aids in smoother shifts. Wear at the casting bores that house these pistons results in loss of AFL pressure and will negatively impact all shifts and EPC pressure. Sonnax oversized actuator feed accumulator piston kit 124740-40K, with tool kit 124740-TL40, can repair worn castings on 6T70 applications and restore lost AFL pressure. These types of small pistons and springs can also be found in the Ford 6F35 second generation valve body (Figure 2).

| Figure 2: 6F35 Gen. 2 Solenoid Damper |

|---|

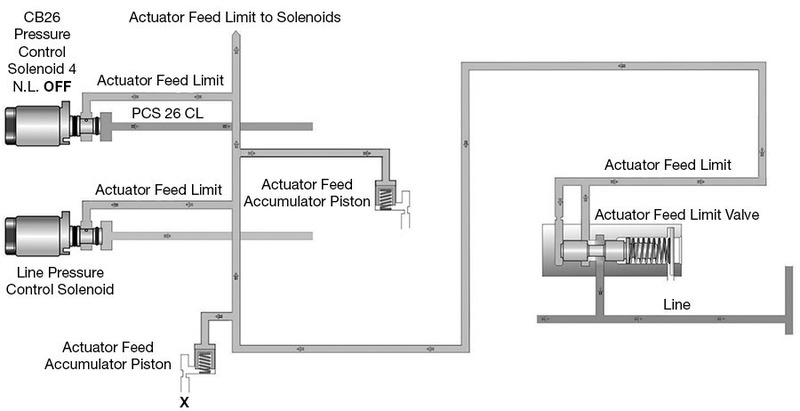

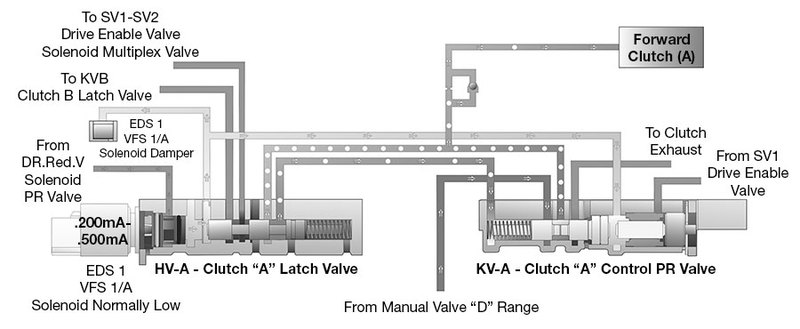

A similar approach for dampening the solenoid pressures is taken on the Ford 6R60 and ZF6HP transmissions. In these units, however, the accumulator is called a solenoid damper and is placed on the output side of each solenoid (Figures 3 & 4).

| Figure 3: Ford 6R60 & ZF6HP Solenoid/Clutch Apply Circuit |

|---|

| Figure 4 |

|---|

|

In the Ford 6R60 and ZF6HP units, the accumulator is called a solenoid damper |

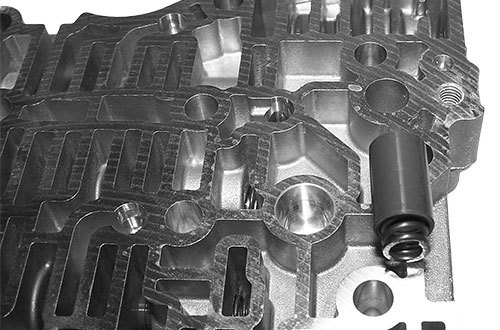

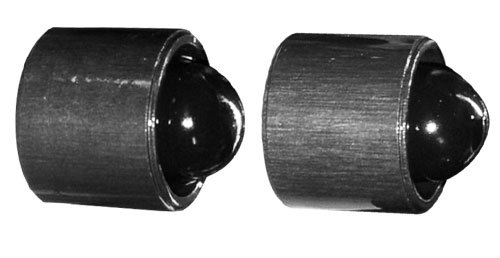

This ensures the stability of the pressures coming from the various clutch apply solenoids and being directed to the specific clutch regulator and associated latch (boost) valves to aid in smoothing the clutch apply. Additionally, instead of a traditional piston and spring approach, OE utilized a rubber tip on the solenoid damper piston for the resistance force. These have been known to flatten (Figure 5), which results in no accumulation of force and shift complaints. Replacing these rubber-tip pistons with Sonnax accumulator piston kit 95740-15K will prevent reoccurring problems in this area.

| Figure 5 |

|---|

|

The dampers’ rubber tips have been known to flatten, which results in no accumulation of force and shift complaints. |

As transmission controls continue to evolve, it’s important to understand the purpose of new types of components and what results when their functionality is compromised. Be on the lookout for these small accumulator pistons/solenoid dampers in later-model units and watch for wear that can compromise proper shifting.

Maura Stafford is a Sonnax product development manager for transmission components and remanufactured valve bodies. She is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.Learn More

Related Units

Related Parts

Required

Recommended

6F35 (Gen. 1) • 6F35 (Gen. 2) • 6F35 (Gen. 3) • 6R100 • 6R140 • 6R60 • 6R75 • 6R80 (2009–2014) • 6R80 (2015-Later) • 845RE • 850RE • CFT30 • ZF6HP19 • ZF6HP21 • ZF6HP26 • ZF6HP28 • ZF6HP32 • ZF6HP34 • ZF8HP45 • ZF8HP50 • ZF8HP55 • ZF8HP70 • ZF8HP75

Accumulator Piston Kit 95740-15K

Required

Recommended

6T70 (Gen. 1) • 6T75 (Gen. 1)

Oversized Actuator Feed Accumulator Piston Kit 124740-40K

-

Helps cure:

- Harsh shifts

- Soft shifts

- Solenoid performance codes

Required

Recommended

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.