November 29, 2023

Symptoms:

- Low line pressure

- Various shift concerns

- TCC apply & release concerns

- Overheated fluid

- TCC slip codes

- Delayed engagement

- Burnt clutches

Cause:

Worn, eroded end plugs allow loss of critical TCC signal and LP signal pressures.Correction:

Sonnax O-ringed end plugs restore correct circuit pressures. The O-ring provides additional sealing to reduce hydraulic losses at critical circuits.10L60 (Gen. 1), 10L80 (Gen. 1), 10L90 (Gen. 1), 10R60, 10R80

O-Ringed End Plug Kit

Part No. 105740-13K

You need this if...

View Instructions

Find a Distributor

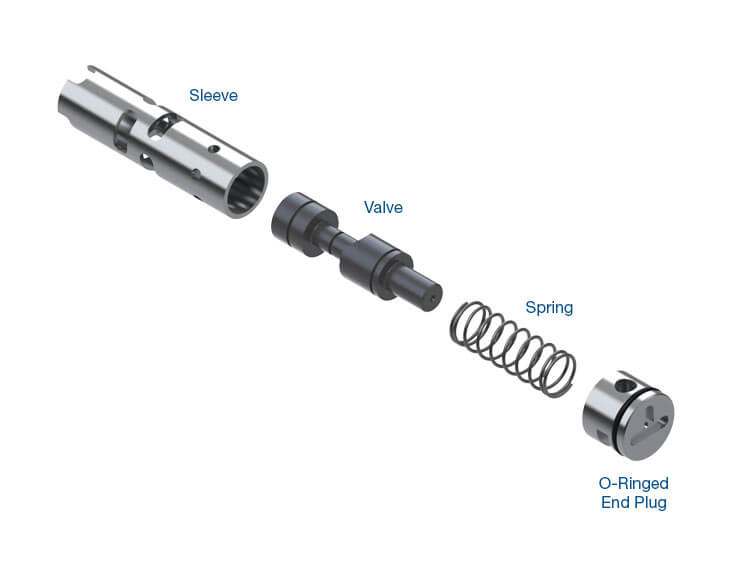

The primary design function of the OE end plug is to prevent critical pressure loss by capping the bore. OE end plugs rely entirely on small clearances between the end plug and bore to confine hydraulic fluid under fluctuating pressure. End plugs are often tasked with a secondary role functioning as a spring stop or valve stop.

The repetitious and varying actions of fluid pressure, spring motion and valve impact cause wear at the end plug and bore mating surface and can distort the shape of the end plug. High pressure fluid leaking through the clearance gap can, with time, erode the surface material of both end plug and bore. Eventually the cumulative loss of hydraulic integrity leads to low pressure in the TCC signal and LP signal circuits. Typical complaints include TCC apply and release concerns, TCC slip codes, low line pressure, and various shift concerns.

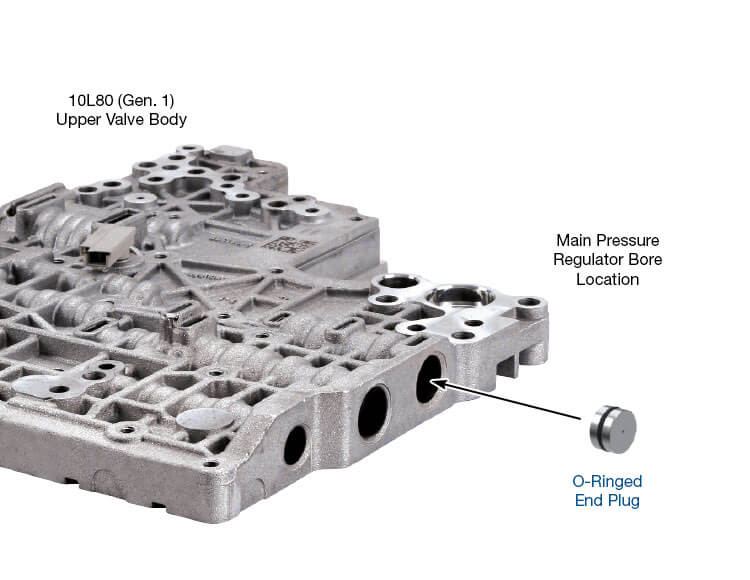

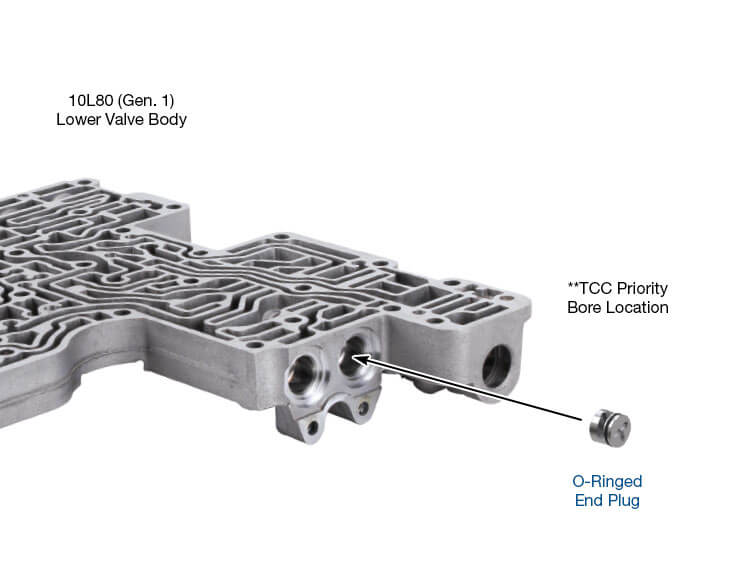

Sonnax O-ringed end plug kit 105740-13K which includes the main pressure regulator valve plug and the TCC priority bore plug replaces worn, distorted or eroded end plugs in listed Ford and GM units. Sonnax end plugs have small clearances to mechanically block the bore and increase effectiveness. The O-ring seal reduces leakage further by blocking off worn areas of the bore which the new end plug alone could not seal.

- Minimal end plug-to-bore clearance with added O-ring for positive seal

- Drop-in Zip Valve™ parts install quickly and easily

- End Plug Large

- End Plug Small

- O-Rings (3) Small, 2 Extra

- O-Rings (3) Large, 2 Extra

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

Ford 10R60, 10R80, 10R140 Valve Body Layout

February 08, 2024

Diagnosing Ford 10R60, 10R80 & 10R140 Series Speed Sensor Issues

Jim Mobley

March 04, 2025

Tackling Ford & GM 10-Speed Valve Body Problems, Failing Batteries & More!

Jim Mobley

You need this if...

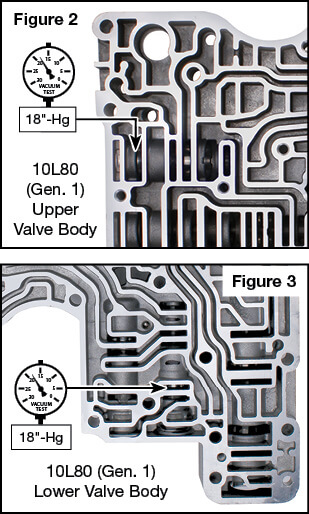

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.