Baseball, Solenoids & Apple Pie: Hitting a Sweet Home Run with 55-50SN Rebuilds

Summer is upon us, which means warmer temperatures, baseball, solenoids and apple pie. Yes, that’s right: solenoids. “What do solenoids have to do with summer, baseball and apple pie?”, you’re probably wondering. Hang in there!

A common saying from the coach to his team on the field is, “Know what you’re gonna do with it.” That’s his way of reminding players to think about the situation. If there’s one out, a runner on first and the shortstop gets the ball, players should know to go to second for the force out with the hopes of turning a double-play at first. Thinking that through before the ball is hit increases the player’s reaction time and – consequently – the chances of a successful outcome. Of course, knowing how the game is played is integral to deciding what the best play IS, not to mention what moves to make.

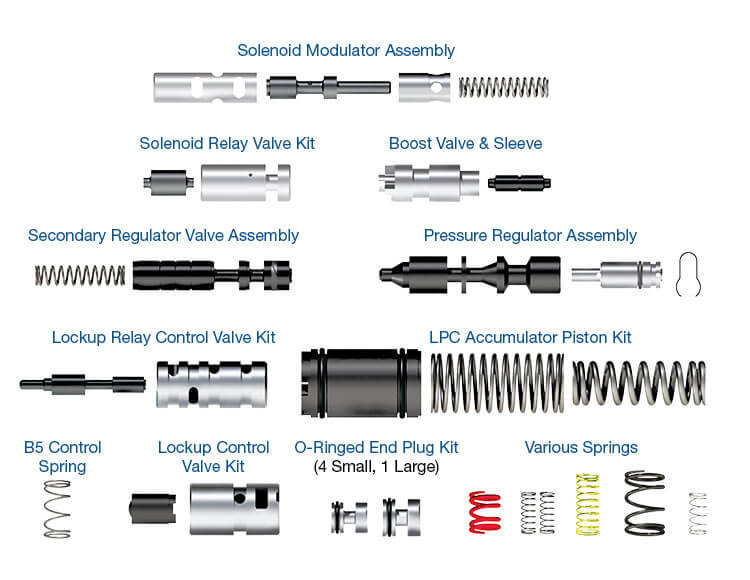

Approaching the common failure of Aisin AW 55-50SN solenoids is very similar to the game of baseball. The primary issue with these solenoids is the sticking nature of the two internal bushings as the ATF or coil temperature increases. Summertime temperatures add to the heat dilemma, particularly in stop/go driving when the cooling system is taxed and the solenoids are exposed to increased heat. Some rebuilders are finding success changing the bushings out, with a variety to choose from. But knowing how these solenoids function and how they work with each other can help determine if there’s a play to make and which is the best choice. Team Sonnax to the rescue!| Figure 1: Valve Body I.D. 55-50SN Late Linear Solenoid Set |

|---|

|

The Lineup

First up to bat: the SLU solenoid that controls the apply and release of the torque converter clutch, the second (B2) clutch and the low and Reverse (B3) clutch. Hard or soft 1-2 and 2-1 shifts, firm/late TCC apply, early TCC apply or no converter lockup all can be attributed to a faulty SLU solenoid. One away!

Next up: the SLT solenoid that primarily controls line pressure in accordance with engine torque at the primary regulator valve. SLT pressure also is directed to the secondary regulator valve to control converter feed pressure and feed the lube circuit. In addition, SLT pressure influences the forward clutch, second coast clutch and 3rd gear band. A multitude of symptoms could occur from a faulty SLT solenoid: harsh/delayed Neutral-to-Drive, harsh Forward, long shifts, low cooler flow, harsh TCC apply, and 2-3, 3-2, 3-4 and 4-3 shift complaints. Two down!

The last to bat: the SLS solenoid that controls clutch apply pressure by regulating Drive or Reverse fluid at the shift pressure control valve to control apply of the 2nd clutch, second coast clutch or direct clutch. This means a faulty SLS solenoid could create harsh Reverse and harsh/flared 2-3, 3-4, 4-5 shifts. The same symptoms can be caused by issues at more than one solenoid, making diagnosis on root cause sticky sometimes. Three down, and now the home team comes to the plate!

Hit a Home Run with Sonnax Remanufactured Solenoids

Sonnax offers sets of 55-50SN remanufactured linear solenoids engineered to address not only the sticking bushing, but a host of other potential failure modes leading to the same drivability concerns. Sonnax improved the bushings with an exclusive new design that incorporates better material, a sizing method for perfect fit and finish every time, plus resists sticking even at elevated temperatures. Base-hit, man on first!

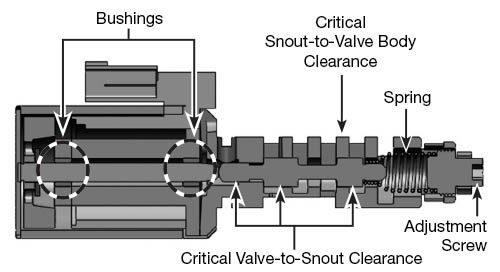

Wear between the solenoid valve and “snout” can result in loss of the critical SLU, SLT, SLS or solenoid modulator pressure, leading to various shift symptoms (Figure 2). Sonnax addresses these concerns by running every solenoid through a rigorous drive-cycle style test on a valve body test machine to ensure that excessive clearance is not occurring and reducing critical pressures. Single up the middle, men on first and second!

| Figure 2 |

|---|

|

| Wear between the solenoid valve and “snout” can result in loss of the critical SLU, SLT, SLS or solenoid modulator pressure, leading to various shift symptoms. |

Another potential failure mode is relaxation or coil binding of the internal solenoid spring. Sonnax tests every solenoid for concerns in this area too by verifying that the spring is providing the appropriate force to help correctly position the solenoid valve. Flare over 3rd, bases loaded!

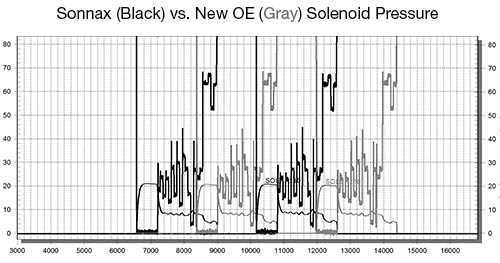

Finally, one of the most difficult and time-consuming issues with these linear solenoids is adjusting the pressures. By turning the adjustment screw inward or outward, the spring force on the valve is altered, which increases or decreases the SLT, SLS or SLU solenoid pressure. Because these solenoids are so interdependent, small adjustments can affect many areas in the drive cycle. Getting each properly adjusted to the now-aging transmission and to any other corrections made to the valve body, clutches, etc. is no easy task. Sonnax solves the adjustment dilemma by incorporating a pre-calibration setting on each solenoid that works across vehicle platforms, eliminating time-consuming tuning at the shop after installation (Figure 3). Grand-slam!

| Figure 3 |

|---|

|

| Sonnax pre-calibrates the 55-50SN remanufactured solenoids to precisely match OE performance, eliminating the need for tuning after installation. |

In addition to sets of fully tested and calibrated linear solenoids, Sonnax provides a full array of 55-50SN solutions for various shift concerns, including a 55-50SN Zip Kit that addresses the most common issues without the need for reaming. Now that’s as sweet as a plate of warm apple-pie with some vanilla ice-cream!

Related Units

Related Parts

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.