Signal Accumulators & Solenoid Dampers: Their Function & Impact on Drivability Complaints

Maura Stafford

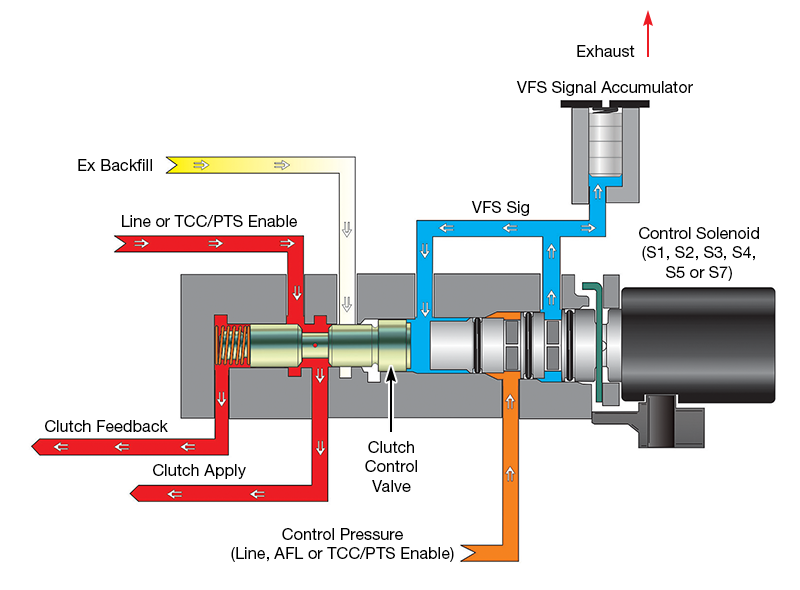

As transmissions continue to add more speeds, the timing between shifts and the clutch overlap is much more critical to achieve the smooth shifts that customers demand. Much of this can be controlled by the computer, which monitors and adapts to the transmission as miles add up. Six speeds and up for many transmissions has meant a transition from shift valves to dedicated clutch control valves that meter fluid pressure to apply and release associated specific clutches. And what controls these valves are dedicated solenoids that regulate the AFL pressure to a VFS signal fluid pressure (Figure 1). This hydraulic circuit arrangement allows for the quick and coordinated concert of different solenoids, valves and clutches applying and releasing with the precision required.

| Figure 1 – Typical Clutch Control Solenoid Circuit |

|---|

|

Another increasingly more common component added to this type of circuit is a signal accumulator or solenoid damper valve. These small little pistons, typically about .300" in diameter, are often found in the valve body or channel casting worm tracks.

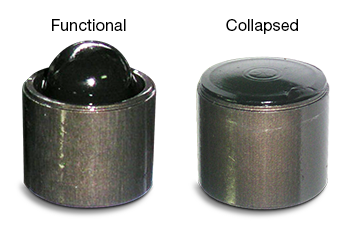

Some of the first applications to include these were the ZF6HP26 and Ford 6R60, which use a unique rubber damper instead of a traditional spring to act as the cushioning force (Figure 2). This same design is used in 6F35, 6R100, 6R140, 845RE and ZF8HP applications.

| Figure 2 – Solenoid Dampers |

|---|

|

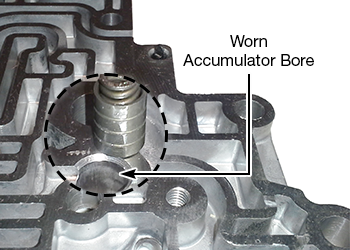

A more conventional spring and piston accumulator is used in the 6T40 (Generation 2 and 3), 6T70 and 8L90 applications (Figure 3). These little accumulators are used to help control the shift feel of the specific circuit by dampening any pressure and flow instabilities that could affect the related control valve. As a result, these very active pistons wear the casting bores or experience rubber damper collapse.

| Figure 3 – Signal Accumulator Piston |

|---|

|

These problems prevent proper function in smoothing the signal pressure acting upon the clutch control valves and can negatively impact the resultant shifts. Worn castings also create a path for the critical AFL or VFS signal fluid pressure to exhaust, resulting in delayed or incomplete stroking of the clutch control valves, which can create shift complaints, burnt clutches and solenoid/EDS codes.

Checking for casting wear or damper damage that could result in drivability complaints can be a quick visual look or simple vacuum test and should be part of your standard rebuild process. Sonnax offers various drop-in and oversized parts to address these issues in all the applications mentioned.

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.