Toyota FWD 6-Speed Lockup Strategy

Eric Streed

Toyota uses what they call “flex” lockup strategy in U660E and U760E transmissions, as well as other models. What exactly is flex lockup? To oversimplify it, it’s a partial slip lockup strategy. Wait, isn’t slipping a clutch a bad thing? Not always. In this article, we will explain why exactly Toyota uses this strategy.

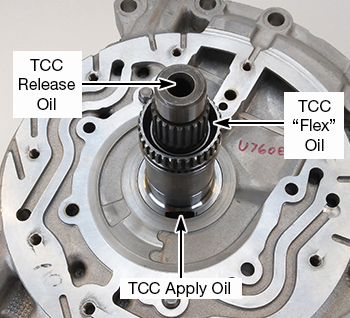

Toyota, like other manufacturers, has added more gear ratios to their transmissions to improve vehicle fuel mileage. When bringing the engine RPM down and cylinder pressure up, vibration transfer is very high. To eliminate this vibration, Toyota slips the converter a very small amount, usually 10–30 RPM. They use flex lockup strategy to accomplish this partial slip. When running in flex mode, heat is being generated by the partial slip of the lockup piston. Oil flow is needed to remove this heat. Flex oil is a third converter oil controlled by the lockup control valve in the valve body (Figures 1 & 2).

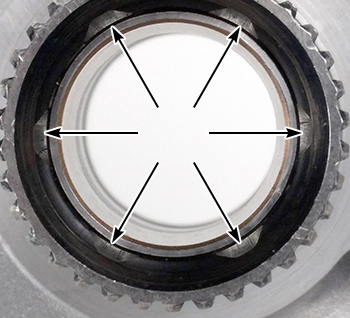

| Figure 1 – U760E Pump Cover | Figure 2 – Six U760E Pump Cover Passages in Front of Stator Support |

|---|---|

|  |

In flex mode, oil enters the converter through the apply passage (Figure 1) and exits converter through flex passage (Figures 1 & 2). There is very little oil flow from the apply to release side of the TCC piston with a conventional converter lining versus a woven material like GM uses. This problem is solved by adding a “flex” passage. When accelerating at light to mid throttle, the TCM commands about 30% duty cycle (500 mA), which creates a partial slip/flex lockup available in all gears. Under light throttle, the SLU solenoid is active at 30%, even during the shifts. Once the car is up to approximately 50 mph at steady cruise, lockup command goes to about 50–55%, which eliminates all slip. At higher speeds, engine load is low, so vibration transfer isn’t a large issue and “full lockup” is okay at higher speeds. In full lockup, the system changes back to that of a two-path converter. With no heat generation in full lockup, there isn’t a need for oil flow in the converter, so flex oil is now blocked in the valve body.

Toyota also uses a strategy on mid-throttle acceleration in which the slip of the converter is increased during upshifts. This makes the overall engine speed change less during shifts. Toyota is using increased TCC slip during shift to lower the ratio change, which makes for great shift feel.

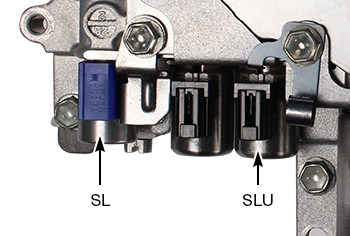

One unique feature for the U660/U760 family is that the SLU linear solenoid is used for engine braking and lockup control (Figure 3). The SLU solenoid controls both the B2 clutch and lockup piston. How is this accomplished? When the on/off SL solenoid isn’t energized, SLU solenoid controls B2 clutch for engine braking in manual 1st Gear. When the SL solenoid is energized, SLU is now used for lockup control. Lockup can be commanded in all forward gears.

| Figure 3 – U760E SL & SLU Solenoids |

|---|

|

With all these demands placed on SLU solenoid, one can see how a malfunctioning solenoid can cause several drivability complaints. There are small holes in the iron core of the SLU solenoid used for control of the magnetic field. When these holes get plugged with debris, the SLU solenoid won’t function correctly. These solenoids also stick from contamination. TCC shudder is another common complaint with these units. If the vehicle spends a lot of time in city traffic in flex mode, partial slip wears out friction material. Notice in Figure 4 how the outside edge of friction is worn.

| Figure 4 – U760E Lockup Piston with Worn Friction |

|---|

|

The piston and cover both have intentional opposing tapers. These surfaces aren’t flat; only the outside edges touch at low converter pressure. This helps to eliminate TCC shudder. When the difference from TCC apply to TCC release pressure increases, the piston will intentionally distort and allow more contact between the friction and TCC covers.

Valve wear can also be an issue if the vehicle spends much of its life in flex mode. If the unit you are working on is a city car, be sure to vacuum test the lockup control valve during rebuild. In flex mode, this valve is always moving, causing bore wear. Knowledge is power. Once you know how a system works, you can fix it.

Related Units

While Sonnax makes every effort to ensure the accuracy of technical articles at time of publication, we assume no liability for inaccuracies or for information which may become outdated or obsolete over time.