September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

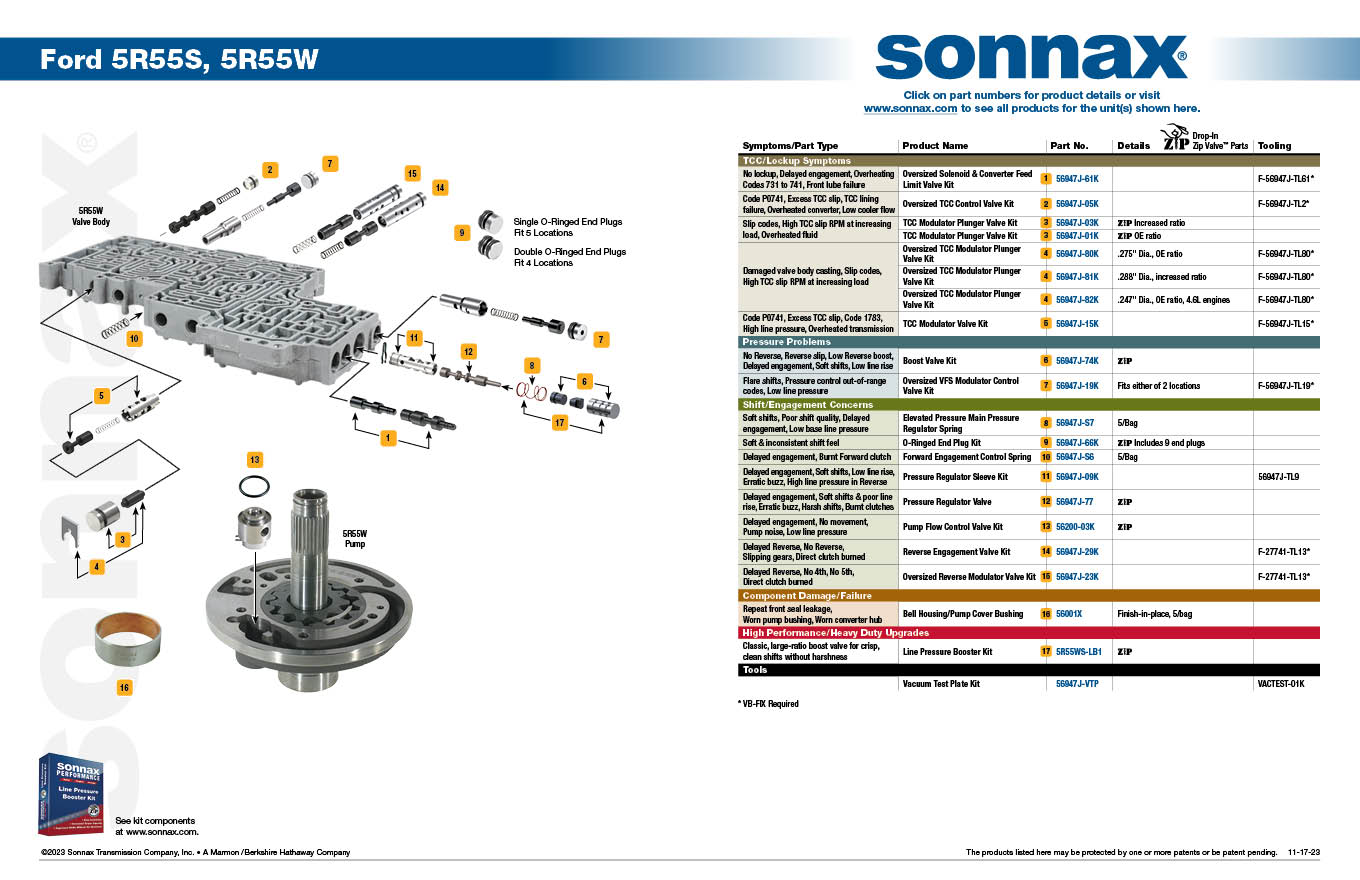

Some common complaints associated with Ford 5R55W and 5R55S are high TCC slip RPMs under increasing loads, slip codes and converter apply or release concerns. These complaints are often caused by wear at the ID of the TCC modulator plunger valve sleeve, due to constant oscillation by the pulse width modulated TCC solenoid. This plunger valve positions the TCC modulator valve, which feeds line to the apply circuit, which controls slip rate. Wear of the sleeve will allow the TCC slip rate to continue to rise, and could prevent full lockup. Another path for hydraulic leakage can be created by the OE retaining clips raising a burr on the TCC modulator sleeve, which gouges the casting bore during disassembly.

Sonnax oversized TCC modulator plunger valve kit 56947J-81K restores hydraulic integrity to the TCC solenoid circuit with precisely toleranced parts. The elevated modulated pressure will not raise apply pressure to the point of TCC piston fatigue, and will result in firmer TCC apply and reduced slip RPM in heavier use applications. A new design retaining clip prevents future burr creation on the sleeve that results in valve casting damage and leakage during disassembly.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

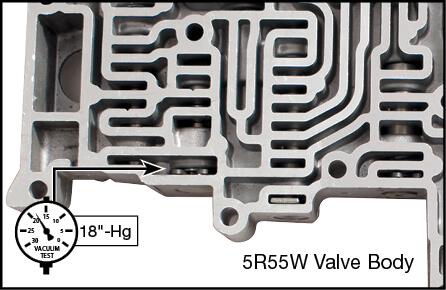

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.