6L80, 6L90

High Capacity 4-5-6 Clutch Apply Piston Kit

Part No. 104960-20K

Use with Powerglide-style, 45-tooth frictions, Sonnax steels & 45-tooth 4-5-6 hub.

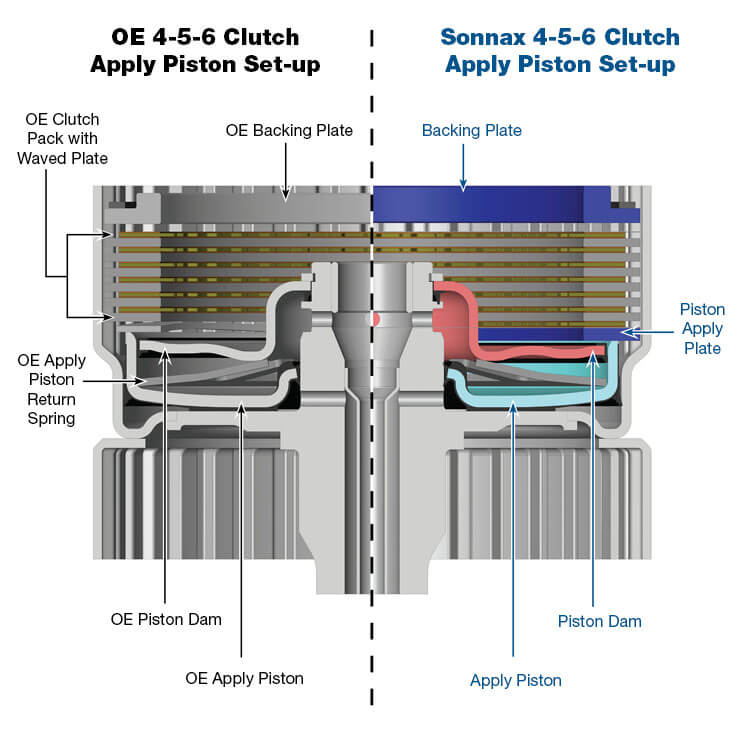

View Instructions Find a DistributorGM 6L80 and 6L90 transmissions often suffer failure of the 4-5-6 clutch assembly due to OE design shortcomings. Not enough clutches and insufficient clutch piston-to-plate apply surface area causes clutch plate failure, especially when apply pressures exceed OE specifications. The other problem is flexing and bowing of the backing plate (coning), which is a primary source of clutch failure.

Sonnax high capacity 4-5-6 clutch apply piston kit 104960-20K features a modified OE clutch apply piston and piston dam that are used in conjunction with a specially-designed toothed apply plate closest to the piston. The Sonnax toothed apply plate increases surface area between the apply piston and first friction plate resulting in more even distribution of apply force to clutch plates and allows a friction plate to run against the apply plate. This configuration eliminates OE waved plate. Since Powerglide-style, 45-tooth frictions are a popular 6L80/90 upgrade due to their wider friction surface, the toothed apply plate and the backing plate have a smaller inner diameter to accommodate that style. For best performance, use with Sonnax steels 104120-01 or 104120-02, BorgWarner high-energy frictions 104120-03 and Sonnax extreme duty 4-5-6 clutch hub and intermediate shaft 104680-45 (for 6L80) or 104690-45 (for 6L90).

- Solid backing plate design outperforms OE and aftermarket plates

- Toothed apply plate eliminates waved plate and allows for additional clutch capacity

- Use with Powerglide-style frictions, Sonnax steels and aftermarket, 45-tooth, 4-5-6 clutch hub

- Backing Plate

- Apply Plate

- Piston Dam

- Apply Piston

-

Patent

- Pending