September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

OE end plugs are designed to capture the valve train in the bore, retain critical oil pressure and function as a spring or valve stop. Repetitive spring movement, valve impacts and abrupt fluid pressure variations promote wear of the end plug circumference and bore I.D. surface, eventually allowing vital oil pressure to escape the circuit.

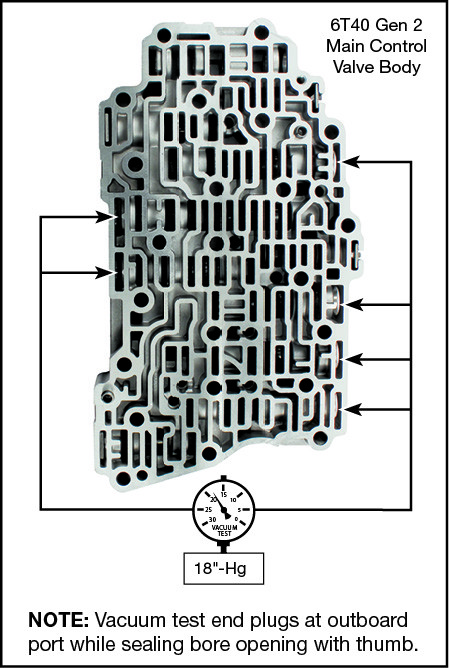

GM Gen. 2 6T30/40/45/50 and Gen. 3 6T35/31/41/46/51 valve bodies have end plugs at the various clutch regulator valve bores that are susceptible to the wear conditions described above. When actuator/solenoid feed pressure leaks out of the affected circuit, various shift concerns and burnt clutches will result. A worn TCC regulator end plug or clutch select valve end plug allows critical oil pressure loss leading to drivability complaints. Reduce or eliminate leakage and restore hydraulic integrity by installing Sonnax O-ringed end plug kit 144510-14K.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

May 25, 2017

Vacuum testing at the port(s) indicated fails to hold the recommended minimum in-Hg, or if wear is visually detected.