September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

Forward Modulation Bore

EPC (electronic pressure control) is the most critical pressure for keeping these transmissions functioning properly. However, constant oscillation of the forward and reverse modulation valves, EPC boost valve and shift end plugs creates casting bore wear that allows this valuable EPC pressure to exhaust. Installing a new EPC solenoid may raise EPC pressure enough to get the unit out the door, but unless the worn circuits are addressed, longevity is severely compromised. In the forward modulation valve bore, looseness of the outboard end plug allows EPC to exhaust, preventing the valve from stroking and creating forward engagement problems. Wear at the large spool on the forward modulation valve causes delayed forward, slide 1-2 shifts, no 3rd gear, and/or low EPC pressure. The bore plug that separates the forward modulation valve from the EPC booster valve also oscillates due to opposing spring and oil forces, creating bore wear and a path for EPC oil to exhaust. Constant oscillation of the EPC booster valve creates both bore wear and a ridge that allows the valve to stick, which can cause erratic EPC pressure, harsh shifts, or poor line rise. The forward modulation bore portion of this Sonnax kit offers numerous improvements over the OE design and refurbishes the hydraulic integrity of the worn casting bore.

Reverse Modulation Bore

In the reverse modulation valve bore, looseness of the outboard end plug allows EPC pressure to exhaust, preventing the valve from stroking and creating reverse engagement problems. The bore plug that separates the inner and outer reverse modulation valves also oscillates due to opposing spring and oil forces, creating bore wear and a path for EPC oil to exhaust. Constant oscillation of both the inner and outer valves creates bore wear that allows clutch apply oil to exhaust, which can result in no 3rd gear. The reverse modulation bore portion of this Sonnax kit offers numerous improvements over the OE design and refurbishes the hydraulic integrity of the worn casting bore.

Shift Valve End Plugs

The plug separating the EPC solenoid from the 1-2 shift valve becomes very loose due to opposing forces and allows EPC oil pressure to flow past and stroke the 1-2 valve, causing 2nd gear starts. The 2-3 shift valve plug becomes loose in the bore due to opposing forces, allowing EPC oil to exhaust. The Sonnax kit provides replacement end plugs for these locations to restore hydraulic integrity.

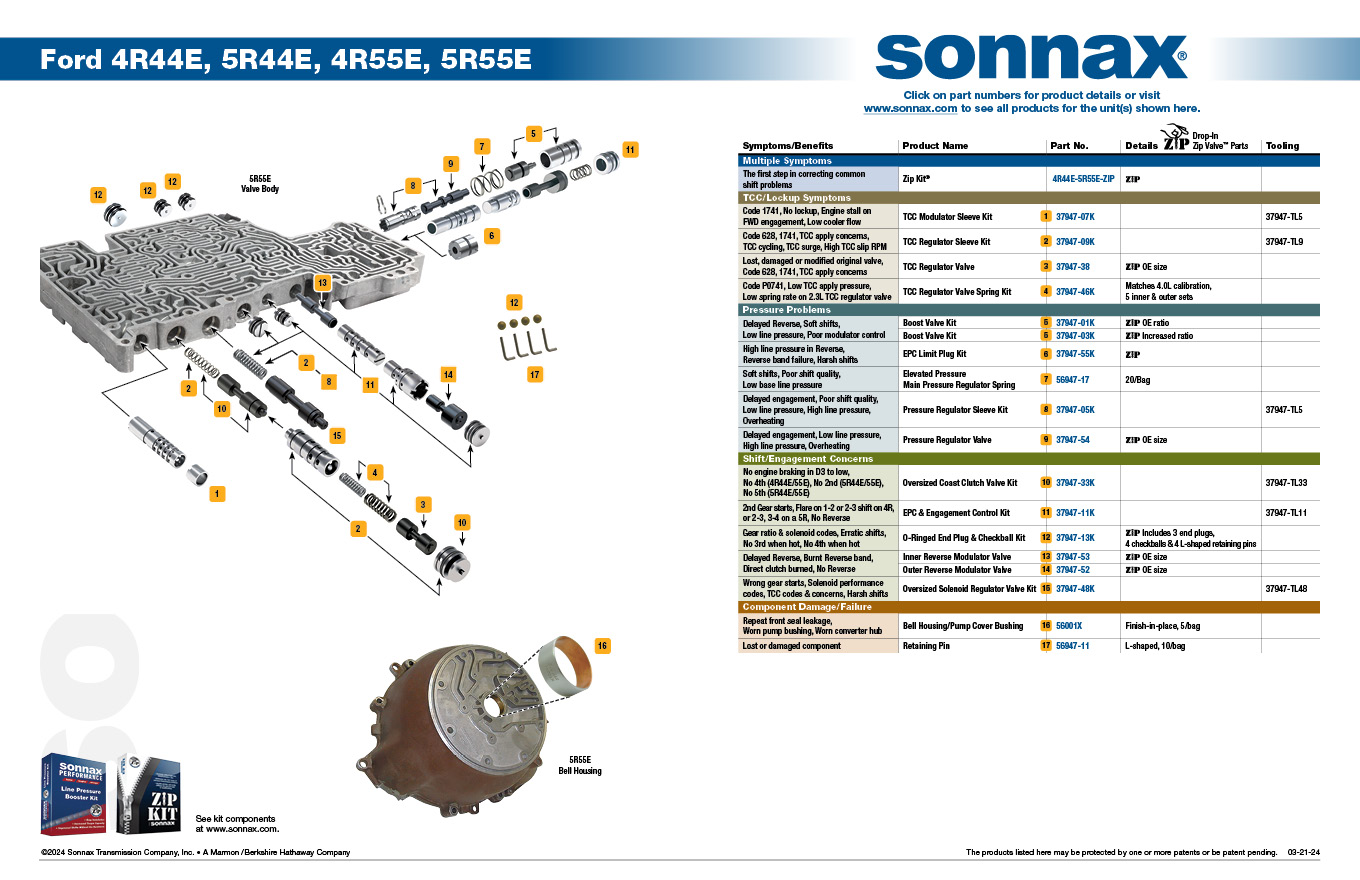

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

September 21, 2005

Bob Warnke

May 21, 2013