August 21, 2013

Symptoms:

- Shift concerns

- Burnt clutches

Cause:

Wear of the end plugs allowing valuable actuator/solenoid feed pressure to leak at the various regulator valves and Reverse and latch pressure to leak at the clutch select valves.Correction:

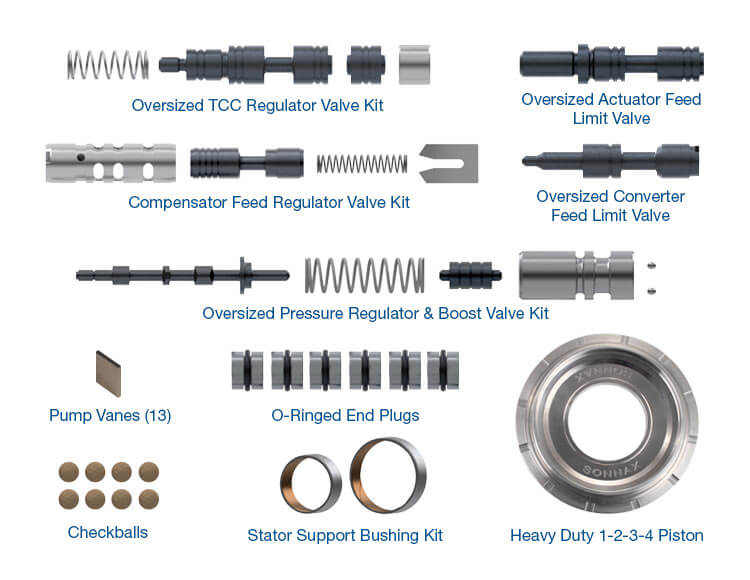

Sonnax drop-in O-ringed end plug kit restores correct circuit pressures. The O-ring provides additional sealing to reduce hydraulic losses at critical circuits.6L45, 6L50, 6L80, 6L90

O-Ringed End Plug Kit

Part No. 104740-23K

You need this if...

View Instructions

Find a Distributor

The primary design function of the OE end plugs is to prevent critical pressure loss by capping the bore; it also performs a secondary function as a spring stop or valve stop. The repetitious and varying actions of fluid pressure, spring motion and valve impact cause wear at the end plug and bore mating surface. Eventually the cumulative loss of hydraulic integrity leads to low pressure in critical circuits.

In GM 6L45, 6L50, 6L80, 6L90 valve bodies, the end plugs at the various clutch regulator valves seal actuator/solenoid feed pressure that is critical to controlling the valve as gears change and clutches apply. When this fluid pressure is allowed to leak due to plug wear, various shift complaints and burnt clutches will occur within those specific circuits. Loss of Reverse and latch pressure occurs at worn plugs at the clutch select valves, preventing proper control of circuits as line pressure is routed through these valves to feed various clutches depending upon gear selection. Sonnax O-ringed end plug kit 104740-23K corrects these issues.

- Minimal end plug-to-bore clearance with added O-ring for positive seal

- Drop-in Zip Valve™ parts install quickly and easily

- End Plugs (7)

- O-Rings (9) 2 Extra

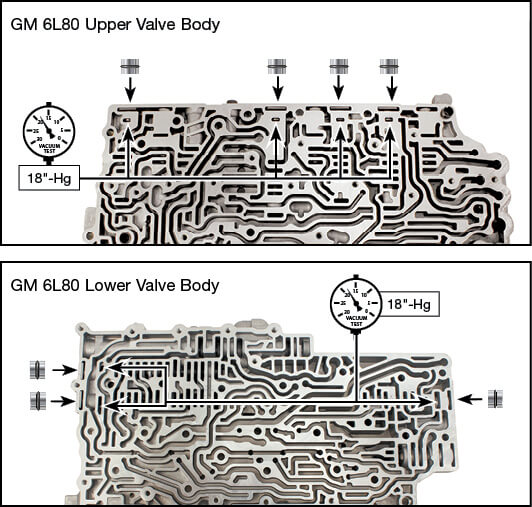

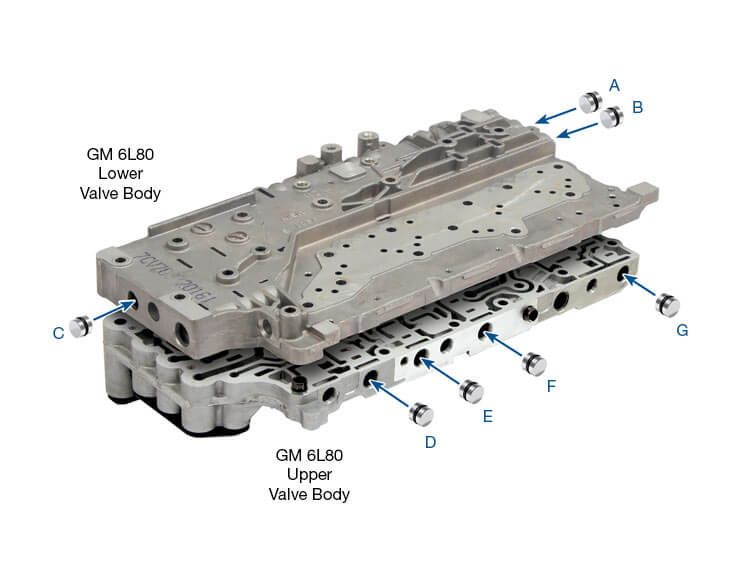

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

GM 6L45, 6L50, 6L80, 6L90 Valve Body Layout

March 08, 2023

GM 6L45/50, 6L80/90 No Movement Conditions: Analysis & Repair Tips

Jim Mobley

You need this if...

Vacuum tests at the ports indicated fail to hold the recommended minimum of 18 in-Hg.