Lead Sled Lea Levels Up Her Powerglide

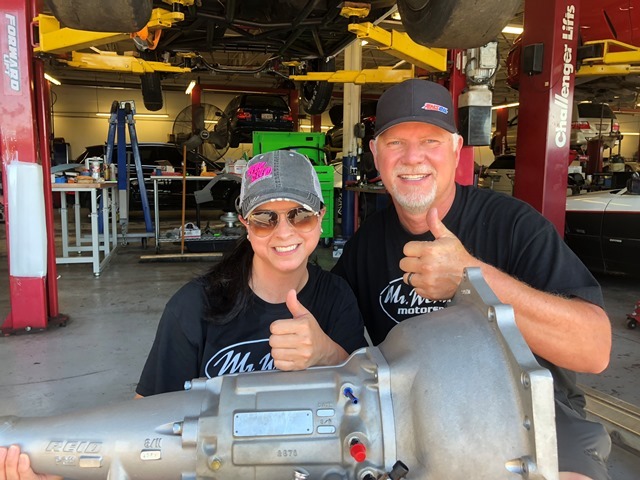

The Lead Sled Resurrection’s cutting-edge Powerglide gets two big thumbs up from driver Lea Ochs and custom transmission builder Wendell Dunaway of Mr. Wendell’s Motorsports fame.

The Sonnax Edge: Lea’s Custom Powerglide Build (Click the links below to learn more.)

- 1.58 Extreme Planetary Assembly

- Ring Gear Stabilizer Kit

- Extreme Strength Output Shaft & Ringless Input Shaft

- Smart-Tech® 10-Clutch Drum Kit

- Smart-Tech® Ratio-Style Servo Kit

- Torque Converter Mechanical Diode®

Bringing a driver and their car back from a devastating crash is not something everyone can do. The new name of Lea Ochs’ iconic Ford Fairmont wagon — Lead Sled Resurrection — says it all. After her original car wrecked on the wall at a 2017 Redemption No Prep series event, she and husband Gary Ochs decided not only to keep racing, but to go bigger and better in every way. Her new car was built from scratch with help from some of the top names in drag racing, including one who happened to be trackside the day of the crash: custom transmission builder Wendell Dunaway of Mr. Wendell’s Motorsports.

Wendell is one of the busiest guys in the business. Famed for Powerglide and 400 builds in some of the world’s fastest cars and his work with Street Outlaws celebrities like Monza, Dominator and Chuck Seitsinger, he’s equally as proud to build for bracket racers on tight budgets. Transforming Lea’s old Powerglide into a sleek, high-horsepower titan that would have her back on any surface, at any venue, was right up his alley. Wendell was following Lea’s success on social media long before he met her in person.

“She works so hard at everything she does, there was no doubt in my mind that Lea was an up-and-comer,” Wendell said. “Here she was investing in a new build and a big new engine with twice the horsepower…and there’s that saying you hear so many transmission specialists complain about: ‘The budget stops at the flywheel.’ You also need to think about upgrading the transmission and work with a reputable builder to get that matching piece of the puzzle. I wanted to be part of her program.”

Like any good builder, Wendell has a deep respect for his customers and typically never talks in detail about their specific setup. Lea is proud of her custom build, though, and makes no bones about the fact that she wants the world to know she is a serious — and capable — competitor.

“We don’t want to just be No Prep people,” Lea said. “Our goal was to make the Lead Sled better than the last one, every single piece of the car, and show off what we can do: Ultra Street, Limited 275, Small Tire, Outlaw Street, True Street, Drag Week. The Powerglide’s perfect because of the flexibility it gives us, and — thanks to Wendell — I’ve got the best of the best. I don’t have to think about the transmission or worry about it at all.”

While some racers have made the switch to the 400, especially since the No Prep scene exploded, Wendell emphasized that the Powerglide’s efficient design, customizable performance and unrivaled consistency makes it ideal for drag racing.

“High-horsepower cars and heavy cars…people have a tendency to want to put a 400 in it,” Wendell said. “I argue with them all the time: I’ve got Powerglides in mud trucks, in monster trucks where the wheels are 1,100 pounds apiece, and you’re telling me a Powerglide can’t handle your 3,500-pound car? Plus, the cost to build a Powerglide is significantly less than what it would cost to build the 400 and get the same consistency.”

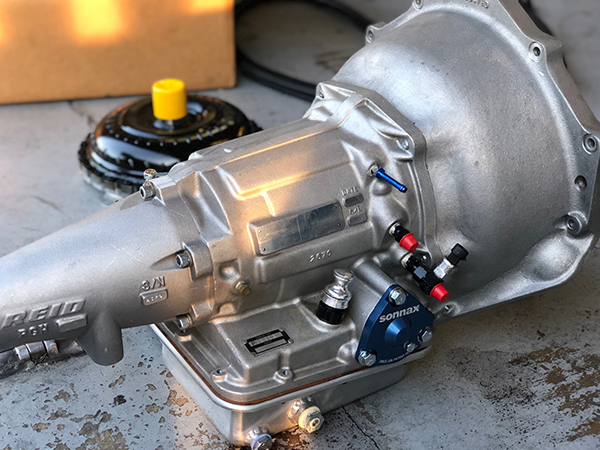

GETTING THE POWER TO THE GROUND: The blue Sonnax servo is a dead giveaway that there’s a lot more going on inside Lea’s Powerglide than might meet the eye.

Packed with Sonnax transmission upgrades rated for 2,500+HP and a race-ready converter, it’s fully capable of handling everything her new car — the Lead Sled Resurrection — can throw at it.

Lea’s old transmission had only one significant upgrade: the Sonnax 1.58 planetary gear set. She switched to this unique ratio from a 1.80 several years before and was happy to keep it with Wendell’s blessing.

“You can always feel when you pick up horsepower,” Lea said. “We picked up like two tenths just swapping the build with the 1.58 because the shift is quicker and easier to handle, much less violent. The lower ratio has been like night and day.”

“She’s running a small-block, LSX motor that Gary built, so the 1.58 is perfect,” Wendell said. “It’s predominantly used in classes that allow nitrous, turbos and prochargers. You need to slow that driveshaft speed down to allow the car to work, and the 1.58 ratio does that, then all of a sudden you’re putting more power to the launch than you normally would with the other gear ratios that are out there.”

The 1.58 gear set really put Sonnax on the map with the Powerglide about eight years ago, Wendell said. The company had decades of experience developing innovative repairs for transmissions and torque converters, and it took that same approach to Powerglide upgrades: Go after the root cause of the problem. In drag racing, the problem is POWER. Just like Lea, nobody is making less of it, and old-school Powerglide builds can’t handle modern engine output. Today, the 1.58 gear set is only one among dozens of Sonnax upgrades that keep the Powerglide competitive at every level of drag racing.

Wendell helped bring Sonnax on board to sponsor Lea’s build. In addition to her 1.58 gear set, she’s fully outfitted with the company’s extreme duty input and output shafts, unique ring gear stabilizer, Smart-Tech servo and Smart-Tech 10-clutch drum.

“Fifteen years ago, you still used a lot of the original parts to put a Powerglide together,” Wendell said. “Today you can build a brand-new Powerglide and not have one stock part in it. Just shows the demand for and popularity of the Powerglide. Sonnax is a big part of that. Everybody looks at me as the guy that builds the high-end stuff, but because of the diversity that Sonnax has, the bracket racer that’s only making 800HP can still come to me, and I can still give him a custom build, but it’s not at the same price as what we’re doing with Lea.”

“I think a lot of people don’t put enough thought into the fact that, when you need a good transmission and torque converter, technology has changed a lot in the last few years,” said Lea’s husband, Gary, whom she credits as the mechanical genius behind the Lead Sled. “If you’re not keeping up with that stuff, you’re setting yourself up to fail. The transmission is the bones, and the converter is a tunable piece that can create either a really good pass or cruddy pass. You use an inferior component and, under the stress that we’re putting it under, it’s just a question of when — not IF — it’s going to fail. We did everything we could to eliminate that risk, so this new Lead Sled is a whole different animal. It performs better and drives better than the old one. We did shakedown passes, and our guy was like, ‘Holy smokes, this car — you could drive it with two fingers!’ which is impressive when you’re talking about how fast it actually is.”

Lea deeply appreciates all that Wendell has done for her racing program, she said.

“He builds our transmission, but I also consider him a very good friend. He believed in our team before the car was even finished and wanted to be a part of it. When we were thrashing to get ready for the big reveal — we basically took a shell of a car and rebuilt it in four days — Gary and I hadn’t slept for 48 hours. Wendell came over to help and suddenly said, ‘Hey, you don’t have a new converter.’ I was like, oh shoot! We don’t have a converter! So he reached out to Joe Rivera at ProTorque and got an amazing converter delivered overnight.”

As the Ochs look ahead to a season packed with big races, they’re happy the Lead Sled’s transmission is one thing they won’t have to worry about.

“I don’t think your best-of-the-best motor can perform like it should if you don’t put the attention on the other pieces,” Lea said. “Now I can just get in the car and drive and it performs. If we do have an issue, it’s a quick fix because we partnered with the right people, people we respect, that we like and feel are a good fit. That’s important to me and gives me a lot of confidence.”

Custom Build Details

1.58 Extreme Planetary Assembly

Lower-ratio gear set track proven to 3,000HP gets the power to the ground. Advanced manufacturing and precision engineering guarantee maximum durability from every component.

“If someone comes to me,” Wendell said, "And says my transmission has been working good, but we feel we are leaving some ET (elapsed time) on the table, I immediately tell them that they have come to the right place. Because of the variety of Powerglide gear ratios and upgrades that Sonnax has, we can help them choose what’s right for their application and how much horsepower they are running to get the numbers they are looking for on the track.”

When racers approach Wendell for a custom build, there are some basic questions he starts with: What kind of racing are they doing, what’s the horsepower level, the weight of the car and tire size?

“The other question I ask is: is it a big block or small block?” Wendell said. “That tells me how much torque they have, and when you're talking about torque, then you need to get into the gear ratios, and that also determines whether we tell them they should switch ratios. We're not talking bracket racer anymore, we're talking somebody like Lea.”

According to Wendell, Lea is not the only racer who switched to the unique Sonnax 1.58 extreme planetary assembly and never looked back.

“Out of all the 1.58 gear sets I've sold,” Wendell said, “I've never had anybody come back and tell me to put something else in it.”

Sonnax offers high-quality gear sets in three levels of performance — Contender, Premium and Extreme — in four ratios — 1.80, 1.69, 1.65 and 1.58 — so racers never have to overpay or underspec to get jaw-dropping performance and reliability. It’s not unusual for builders to pull a tranny for refresh and marvel that the Sonnax parts are still flawless after one, two, even three seasons of hard use.

“When you see a Sonnax gear set come out of the box compared to some of the others out there….they don't even hold a candle to Sonnax,” Wendell said. “When you buy Brand X, will it work? Yes, for a little while and usually just enough to get to the end of warranty, but we found there are some problems with the materials and how they are made for a long-lasting life. For longevity and years of performance, you can’t beat Sonnax.”

Ring Gear Stabilizer Kit

Reduces stress on gear teeth when staging and prevents vibration so the planetary runs true for less friction and drag.

Even if they don’t know what the sound means, many drivers have heard the ring gear on their planetary gear set CLUNK as the car is pushed around the pits. It’s the sign of a loose ring gear, which has a lot of play and slop because the ring gear is not supported in any way. It’s just along for the ride. As the trans brake applies, it can hold the ring gear in an un-centered position that stresses the gear set’s small pinion gears.

The Sonnax ring gear stabilizer system bolts onto the carrier and features bearing buttons to create support and prevent the ring gear from wobbling around. Since the stabilizer keeps everything running on-center, there’s less vibration as well — another source of stress removed from the whole transmission. Wendell recommends it to all of his customers, especially for those running 1.58 and 1.65 ratios in the most extreme applications.

Extreme Strength Output Shaft & Ringless Input Shaft

Guides power safely through the transmission thanks to innovative design and ultra-high-strength materials to stop spline twist and breakage.

“The 1.58 was the only Sonnax part in Lea’s transmission when I first opened it up,” Wendell said. “The input shaft was of an obviously inferior material, and when she went from the original Lead Sled to the Resurrection, she went up in horsepower dramatically by going to the turbo setup. An upgraded input shaft was crucial for her to take that next step. She’s now got the Sonnax ringless input shaft at one end to go with the Sonnax output shaft from her original 1.58 setup on the other.”

Track proven to stand up to the most extreme horsepower, Sonnax cut no corners when developing output and input shafts to pair with its gear sets. Precision manufactured from high-strength materials, the shafts feature advanced torsional designs, rolled splines and other cutting-edge features for outstanding performance and ease of installation.

For racers deeply worried about input shaft failure, the Sonnax big shaft input shaft system adds even more durability with a 1-1/8" shaft that’s 35% stronger than standard 1" shafts. It’s the only big shaft upgrade with custom components designed to work together for reliable performance. Once you have the shaft and other required parts for use with Sonnax gear sets, a simple change to a 35-spline turbine hub is all that’s required to level up with this unique system. According to Wendell, he has several customers running this input shaft that are well into the 3’s (seconds) in the 1/8 mile with no issues or breakages.

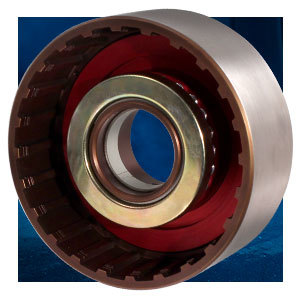

Smart-Tech 10-Clutch Drum Kit

The original 10-clutch drum system invented by Sonnax packed with a larger piston for 35% more clutch holding power, essential for keeping the gears applied in a high-power vehicle.

“I absolutely love the Smart-Tech clutch drum,” Wendell said. “It works extremely well because the piston is much bigger, which gives you more contact area for the fluid to apply pressure on the piston to hold the clutches in place. When you’re dealing with a lot more horsepower, you deal with a lot more RPM, and more RPM makes it harder to keep those clutches applied. Anytime you can get more hold on your clutches, the better, especially in the high-horsepower applications. The Smart-Tech drum goes in most every high-performance build I do, anything over 1,200HP.”

In addition to more apply area than any other drum on the track, the Smart-Tech 10-clutch drum kit’s components give builders two options. They can reduce line pressure for great efficiency or drop to seven frictions for less parasitic drag and improved heat dissipation (due to the larger piston) while still retaining 10-clutch capacity.

As with other key Powerglide upgrades, Sonnax offers a variety of quality drum options so builders like Wendell can spec out upgrades that work for both the budget and racing ambitions of his customers. From high-quality, direct replacement drum components to five styles of 10-clutch kits, this is another critical area of the transmission Sonnax has fully covered.

Smart-Tech Ratio-Style Servo Kit

Revolutionary servo keeps the clutch applied in even the most extreme applications to guard against band failure, broken shafts and staging issues.

“Sonnax has lots of servo options, but we went with the Smart-Tech servo for Lea,” Wendell said. “I recommend it in all my Powerglide builds and demand it in all my high-performance builds. If people say they really don’t have the budget for it, then I say at the very minimum I want to put in the Sonnax supported servo.”

Wendell’s passion for Sonnax servos is matched by the company’s passion for solving old-school servo problems. The core of the issue is that the antiquated, OE Powerglide servo design is no match for today’s power levels. It suffers from what’s known as the pin bias effect: flaws in the OE servo responsible for otherwise unexplained band failures, input shaft failures and staging issues. Years ago, when power levels were lower, racers could get by with an OE-type servo. As power levels went up, so did line pressure, which aggravated the pin bias effect and led to more burnt bands, broken shafts and a host of other problems that undermined the Powerglide’s reputation for reliability.

Sonnax was the first to expose the pin bias effect and develop products to combat it. The Smart-Tech ratio-style servo’s patent-pending design completely eliminates pin bias and is packed with many more unique features to make it the ultimate servo for even the most extreme applications. The alternative, less-costly upgrade Wendell recommends is the Sonnax supported servo, which counteracts pin bias up to 275 psi. Watch this video to learn more about the pin bias effect and how to combat it.

“The old servos out on the market, they’re janky,” Wendell said. “The way you put them together, there's always a lot of slop involved. They don’t fit very good, and you can tell they just don’t work very well. After they run for a long period of time, they’re grooved and get scores on them — they maybe last 150 passes. Now the Smart-Tech servo, you get more holding power on your band so it doesn’t burn AND it’s lasting 300–350 passes, so ultimately it’s saving you money. The Smart-Techs we’re pulling out during refresh, we just take them apart, look at the band, laugh, clean them up, reassemble them and put them back in. Wear on them is very minimal. You can’t argue with the success that we’re having with them.”

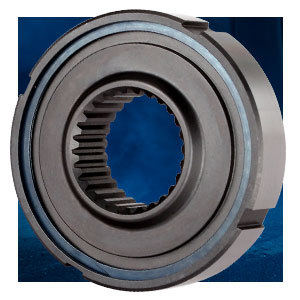

Torque Converter Mechanical Diode

Strong, durable component designed specifically for racing prevents converter failure in high-horsepower vehicles.

Just like Lea’s custom transmission, her new torque converter is a top-of-the-line build from another well-known name in drag racing: Joe Rivera at ProTorque.

“We use the Sonnax 10-strut Mechanical Diodes in all of our high-horsepower builds,” Rivera said. “It’s a critical piece of the puzzle to make these high-horsepower cars perform. We’ve been using them in everything from 1,000HP street cars to 5,500HP race cars and everything in between.”

Racers that know the Sonnax name for performance transmission parts might be surprised to learn that almost every rebuilt torque converter in the U.S. contains Sonnax components. The company is the world’s leading, full-line supplier of everything from innovative, top-quality covers and turbine hubs to multi-plate clutch kits. Designed to prevent converter failure in high-torque applications, Mechanical Diodes are much stronger components than roller-ramps and “dog bone” style sprags while also being substantially smaller and lighter in weight.

The “black box” nature of a sealed converter means, except for the builder, people rarely see components like diodes or the work that goes into selecting and assembling a finished piece. For an inside look at what it’s like to spec out and build a performance converter, check out this video that brings you right into the Sonnax Research & Development shop.

MORE: Want to see what it takes to build a world-class Powerglide racing transmission? Check out this video as high performance guru Gregg Nader shows you everything you need for the ultimate in performance and durability.

View News Archive