September 30, 2005

Anatomy of a Transmission: Oil Flow in the Pump-PR-Converter-Cooler Lube Circuits

Gregg Nader

OE end plugs are designed to prevent critical pressure loss by capping the bore, while also functioning as a spring or valve stop. Repetitive spring motion, valve impact and fluid pressure variations cause wear between the end plug and bore mating surface, allowing vital pressure to escape the circuit.

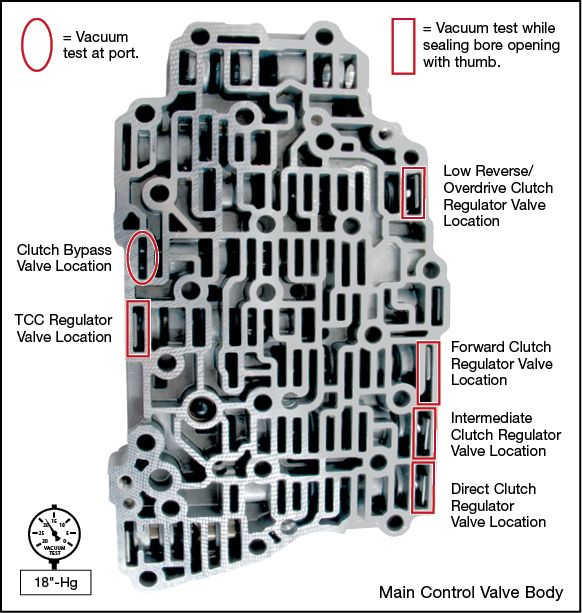

Ford 6F35 (Gen. 1, Gen. 2 and Gen. 3) valve bodies have end plugs at the various clutch regulator valve bores which are susceptible to this wear. When actuator/solenoid feed pressure is allowed to leak due to plug deterioration, various shift concerns and burnt clutches will result in the affected circuit. Wear at the TCC regulator and clutch bypass valve end plugs allows valuable oil loss that leads to drivability concerns. Eliminate leaks and restore hydraulic integrity by installing Sonnax O-ringed end plug kit 147740-03K.

Sonnax valve body layouts provide a detailed overview of individual units making it quick and easy to determine what’s available for the specific valve body you’re working on. See all Sonnax valve body layouts.

September 30, 2005

Gregg Nader

October 31, 2014

June 02, 2023

Jim Mobley

Vacuum tests at the ports indicated fail to hold the recommended minimum 18 in-Hg.

a. Vacuum test five locations (marked with rectangles) while placing thumb over bore opening to seal.

b. Vacuum test the sixth location (marked with oval) at the port indicated.